Zinc alloy is a highly machinable engineering material valued for its dimensional stability, excellent surface finish, and cost efficiency. In CNC machining, it allows higher cutting speeds, reduced tool wear, and consistent repeatability—making it an ideal choice for precision components with complex geometry.

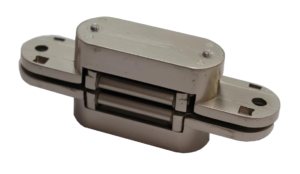

At Dewintech, zinc alloy is commonly used for functional housings, connectors, brackets, and appearance-critical parts, where accuracy and surface quality matter more than extreme strength.

Outstanding Machinability

Low cutting resistance enables fast cycle times and stable machining, ideal for medium- to high-volume CNC production.

High Dimensional Stability

Minimal internal stress and deformation ensure reliable tolerances, even for thin-wall or detailed features.

Excellent Surface Finish

Naturally smooth machined surfaces, well-suited for plating, painting, and powder coating.

Cost-Effective Precision

Compared with aluminum or steel, zinc alloy delivers precise results at lower overall manufacturing cost.

| Property | Typical Value | Unit |

| Tensile Strength | 280 – 350 | MPa |

| Density | 6.6 – 6.9 | g/cm³ |

| Elastic Modulus | 83 – 96 | GPa |

| Melting Point | 380 – 390 | °C |

| Available Processes | CNC Milling, CNC Turning, Drilling, Tapping | |

We routinely achieve ±0.01 mm tolerances, with controlled geometries reaching ±0.005 mm, delivering clean edges, stable threads, and finish-ready zinc alloy parts.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA