In the world of CNC machining, if Aluminum is the athlete and Brass is the artist, then Tool Steel is the heavyweight champion. Tool steel refers to a variety of carbon and alloy steels that are uniquely suited to be made into tools. Why? Because they possess incredible hardness, resistance to abrasion, and the ability to hold a cutting edge at extremely high temperatures.

Unlike regular steel, tool steel contains high amounts of tungsten, molybdenum, manganese, and chromium. These elements are added to ensure the material survives “the grind”—literally. There are several categories you should know:

Water-Hardening (W-series): High carbon content, great for simple parts like cold-heading dies.

Cold-Work (A, D, and O-series): These are the workhorses for stamping dies and gages. The “D” series (like D2) is famous for its high chromium content and wear resistance.

High-Speed Steel (M and T-series): These are designed to stay hard even when they get red-hot from high-speed friction, making them perfect for drill bits and end mills.

Hot-Work (H-series): Developed to resist the heat and pressure of die casting and forging.

| Property | Typical Range | Unit |

| Hardness (After Heat Treat) | 50 – 66 | HRC |

| Density | 7.7 – 8.1 | g/cm³ |

| Tensile Strength | 600 – 2000+ | MPa |

| Thermal Conductivity | 20 – 45 | W/m·K |

| Impact Toughness | Moderate to High | J |

Because tool steel is so hard, machining it requires high-end CNC equipment and specialized carbide tooling. Common processes include:

Hard Milling/Turning: Machining the steel after it has already been heat-treated.

EDM (Electrical Discharge Machining): Often used for tool steel because it can create complex shapes in extremely hard materials that traditional bits cannot touch.

To further enhance its lifespan, tool steel parts often undergo:

Nitridation: Infusing nitrogen into the surface for extreme wear resistance.

PVD Coating: Applying a thin film (like TiN or AlTiN) to reduce friction.

Vacuum Heat Treatment: Essential for reaching the desired Rockwell hardness (HRC).

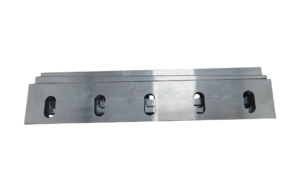

Working with tool steel is a high-stakes task—one wrong cooling cycle or cutting speed can cause the material to crack or warp. Dewintech combines advanced CNC centers with deep metallurgical expertise. We don’t just cut the metal; we manage the entire lifecycle of the part, including precision heat treatment and specialized coatings. Whether you need high-impact mold cores or high-precision industrial blades, Dewintech ensures your tool steel components are built to endure the toughest environments.

Do you have a specific hardness requirement (HRC) for your tool steel parts, or would you like us to recommend a grade based on your application?

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA