If there is a metal that defines the future of aerospace and medical science, it is Titanium. It occupies a unique position in the material world—offering the strength of high-strength steel but with only 56% of its weight. Beyond its physical stats, Titanium is a “noble” metal in the engineering sense; it is virtually immune to the corrosive forces of the ocean and is the most compatible metal with the human body.

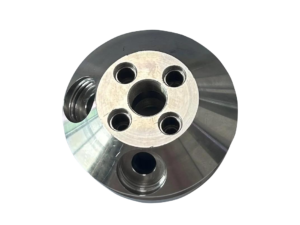

At Dewintech, we don’t just “cut” Titanium; we master it. This material is notoriously difficult to machine due to its low thermal conductivity and tendency to work-harden. Our facility is equipped with high-torque, high-pressure cooling CNC systems specifically calibrated to handle the unique “spring-back” effect and heat concentration of Titanium alloys, ensuring that your most critical designs are executed with flawless precision.

Extreme Power-to-Weight: Why choose between light and strong? Titanium gives you both. It is the gold standard for parts that must survive high stress without adding bulk to the assembly.

The “Immune” Metal: From deep-sea sensors to chemical processing tanks, Titanium creates an instant, self-healing oxide layer that makes it practically rust-proof in even the most aggressive environments.

Human-Grade Biocompatibility: It is one of the few materials that the human body does not treat as a foreign object, making it the premier choice for life-changing implants and surgical tools.

Thermal Stability: While aluminum softens at high temperatures, Titanium maintains its structural integrity, making it vital for engine components and exhaust systems.

| Property | Typical Value (Grade 1 – Grade 5) | Unit |

| Tensile Strength | 240 – 1000+ | MPa |

| Yield Strength | 170 – 900+ | MPa |

| Density | 4.43 – 4.51 | g/cm³ |

| Thermal Conductivity | 6.7 – 22 | W/m·K |

| Elastic Modulus | 102 – 114 | GPa |

| Melting Point | 1650 – 1670 | °C |

| Available Processes | CNC Milling, CNC Turning, EDM, 3D Printing (SLS) | |

Titanium processing is a test of a manufacturer’s true capability. Dewintech brings a refined technical approach to every Titanium project:

Vibration Control & Tool Longevity: We utilize specialized carbide coatings and optimized tool geometries to combat Titanium’s “stickiness,” ensuring clean cuts and avoiding micro-cracks in the material.

Precision Under Pressure: Whether it’s Grade 5 (Ti-6Al-4V) for structural rigidity or Grade 2 for chemical resistance, we hold tolerances of ±0.005mm using multi-axis synchronized machining.

Surface Excellence: Beyond the mill, we offer specialized finishes like Type II Anodizing (for wear resistance) and medical-grade passivation to ensure your parts are ready for immediate high-stakes deployment.

Engineered Reliability: From aerospace turbines to custom dental implants, our quality system tracks every batch of raw material back to its source, providing the transparency required for high-risk applications.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA