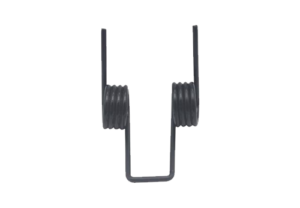

While most metals are designed to stay in the shape they are bent into, Spring Steel is engineered to do the exact opposite. Defined by its incredible yield strength and “elastic memory,” this material is the soul of any component that must endure constant movement, vibration, or compression without losing its original form.

In the world of stamping, Spring Steel is not just a material; it’s a high-tension performance alloy. Whether it’s a tiny battery contact or a heavy-duty automotive clip, Spring Steel provides the “snap” that keeps mechanical systems alive.

Spring steel’s behavior depends heavily on its carbon and alloy content (like Silicon and Manganese). We typically process these in an annealed (softened) state to allow for precise stamping, followed by a rigorous heat treatment to “lock in” their spring-like properties.

| Grade | Common Equivalent | Primary Strength | Best Application |

| 65Mn | AISI 1566 | High hardness & wear resistance | Flat springs, saw blades, clips |

| 60Si2Mn | AISI 9260 | Exceptional elasticity & fatigue life | Heavy-duty springs, leaf springs |

| 50CrVA | AISI 6150 | High toughness & impact resistance | Valve springs, high-load brackets |

| SK5 / SK7 | AISI 1080 | Excellent edge retention | Precision blades, high-tension washers |

Fabricating spring steel is a high-stakes balancing act. Because the material is designed to resist deformation, it presents two unique challenges for the fabricator:

Aggressive Springback: Unlike mild steel, Spring Steel fights against the bending die. We use advanced over-bending calculations and precision CNC compensation to ensure the final angle is exactly what your blueprint requires once the pressure is released.

The Heat Treatment Cycle: To achieve its legendary resilience, the parts must undergo a “Hardening and Tempering” process after stamping. This transforms the steel from a workable blank into a high-performance spring.

Surface Defense: Beyond Rust Protection To prevent corrosion without affecting the material’s mechanical properties, we recommend:

Black Oxide (Blackening): A chemical conversion that adds zero thickness—perfect for tight-tolerance springs.

Phosphate Coating: Provides excellent oil retention for moving parts.

Zinc Plating: Offers a bright, sacrificial shield for parts exposed to the elements.

At Dewintech, we don’t just stamp parts; we manage mechanical energy. We understand that a spring clip isn’t just a piece of bent metal—it’s a component that must perform millions of cycles without fail.

Our facility is optimized for the complete lifecycle of spring steel, from precision progressive die stamping to in-house controlled atmosphere heat treatment. We ensure your parts never become brittle and never lose their “memory.” With Dewintech’s expertise in high-carbon alloys, your most demanding designs will have the resilience to bounce back, time and time again.

Does your part need to survive millions of cycles, or is it a one-time high-tension fastener? I can help you select the ideal heat-treatment hardness (HRC) to ensure your design never cracks under pressure.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA