Nylon (Polyamide) is the industry’s premier choice for applications requiring high impact resistance and exceptional toughness. Known for its ability to absorb vibration and withstand heavy mechanical wear, Nylon is the go-to material for moving parts that must endure friction and stress without failing.

Superior Impact Strength: Highly resilient and difficult to crack, even under repeated mechanical shock.

Self-Lubricating: Low friction coefficient makes it ideal for unlubricated bearings and sliding wear strips.

Vibration Damping: Naturally absorbs noise and mechanical chatter, making machinery run quieter.

Chemical Resilience: Excellent resistance to oils, greases, and many industrial solvents.

| Property | Typical Value (PA6/PA66) | Unit |

| Tensile Strength | 60 – 85 | MPa |

| Elastic Modulus | 2.0 – 3.5 | GPa |

| Density | 1.13 – 1.15 | g/cm³ |

| Water Absorption (24h) | 1.2 – 2.5 | % |

| Coefficient of Friction | 0.25 – 0.40 | – |

| Melting Point | 220 – 265 | °C |

| Machinability | Good | – |

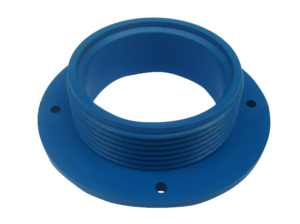

Core Applications: Heavy-duty gears, bushings, rollers, pulleys, and engine-room components.

Glass-Filled Options: We offer GF-Nylon for projects requiring extra rigidity and higher heat resistance.

Surface Finishes: Standard machining, bead blasting for a matte look, or industrial dyeing for custom color coding.

Nylon’s tendency to absorb moisture and expand requires a partner who understands its unique physics. At Dewintech, we utilize specialized cutting tools to prevent material “gumming” and apply precise dimensional compensation to account for humidity factors. We ensure that your Dewintech-produced Nylon parts remain stable, functional, and precise throughout their entire lifecycle.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA