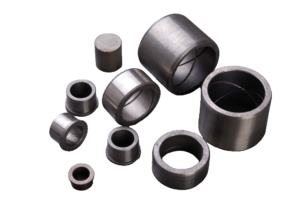

If you’ve ever wondered how car manufacturers produce millions of transmission gears, oil pump rotors, and engine sprockets with almost zero waste, the answer is Iron-Based Powder Metallurgy.

Unlike casting, where we melt the metal, PM is more like “industrial baking.” We take high-purity iron powder, mix it with alloying elements (like nickel or copper), and crush it into a precision mold at massive pressures. The result is a “green part” that has the consistency of a hard biscuit, which we then sinter in a furnace to fuse the atoms together.

In powder metallurgy, Density = Strength. Because PM parts are porous by nature, we categorize them by how “solid” they are:

| Class | Density (g/cm³) | Performance Level | Typical Application |

| Low Density | 6.0 – 6.4 | Self-lubricating properties | Oil-impregnated bushings |

| Medium Density | 6.4 – 6.8 | Good structural balance | Hand tool components |

| High Density | 7.0 – 7.2+ | High fatigue resistance | Heavy-duty automotive gears |

One of the most unique features of iron-based PM is controlled porosity.

Self-Lubrication: We can leave microscopic “holes” in the metal and then vacuum-impregnate them with oil. This creates a “Self-Lubricating Bearing” that can run for thousands of hours without ever needing a drop of grease.

Quiet Operation: Because the material isn’t a solid crystalline block like forged steel, it absorbs sound and vibration. This makes PM gears run much quieter in household appliances and power tools.

Zero Waste (Green Manufacturing): Over 95% of the raw material ends up in the final part. In traditional CNC machining, you might scrap 50% of the metal as chips.

Complexity for Free: We can create “blind” internal keys, complex cam shapes, and non-circular gears that would be impossible or incredibly expensive to mill.

Consistency: Once the steel die is set, the millionth part is identical to the first.

Technical Reality Check: While PM is incredibly cost-effective for high volumes, it has limits. Because we have to “press” the powder, parts cannot have undercuts or holes perpendicular to the pressing direction. Also, PM parts generally have lower impact strength than solid forgings—so if your part is going to be hit with a sledgehammer, we might need to look at Copper Infiltration to fill the pores and add toughness.

Are you looking to replace a complex CNC-machined gear with a more cost-effective solution? Let’s look at your annual volume—if you’re producing over 5,000 units, Iron-Based PM could cut your costs by 30-50%.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA