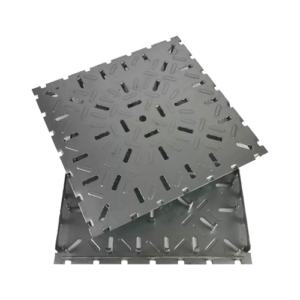

If your project demands immediate corrosion protection without the added cost and lead time of post-process plating, Galvanized Steel is the definitive answer. By coating a carbon steel base with a protective layer of zinc, this material provides a built-in defense against rust, making it the industry standard for HVAC systems, outdoor enclosures, and automotive internals.

No Post-Finishing Required: Because the zinc layer is applied at the mill, parts are often “ready to ship” immediately after stamping and bending.

Self-Healing Properties: If the surface is scratched, the surrounding zinc acts as a sacrificial anode, protecting the exposed steel from oxidation.

Cost-Effective Durability: It offers significantly better longevity than untreated carbon steel at a fraction of the price of stainless steel.

High Formability: Despite the coating, the material remains ductile enough for deep-draw stamping and complex multi-stage bending.

| Feature | Electro-Galvanized (SECC) | Hot-Dip Galvanized (SGCC) |

| Surface Finish | Fingerprint resistant, silky smooth | Visible “spangles” or matte grey |

| Zinc Thickness | Thin and precise | Thick and robust |

| Paint Adhesion | Superior (ideal for appliances) | Good (best for industrial use) |

| Corrosion Resistance | Moderate (Indoor/sheltered) | Excellent (Outdoor/rugged) |

| Common Thickness | 0.4mm – 2.0mm | 0.5mm – 4.0mm+ |

During CNC bending, galvanized steel requires specialized attention. The zinc coating can sometimes “gall” (transfer) onto the bending tools, or in low-quality sheets, the coating may flake at the bend radius. High-quality fabrication ensures that the bend radius is optimized to maintain the integrity of the zinc shield, ensuring no “weak spots” are created where rust could start.

Handling galvanized steel is about protecting the finish while maintaining the form. At Dewintech, we utilize specialized die coatings and polished tooling to ensure that the zinc layer remains intact throughout the stamping process.

Our facility is optimized for high-volume production, where the “pre-protected” nature of galvanized steel allows us to compress your production timeline significantly. Whether you are designing a sleek electronic chassis using SECC or a rugged outdoor bracket using SGCC, Dewintech provides the technical oversight to ensure your parts are as durable as they are precise.

Are you designing for a visible exterior or a hidden internal structure? I can help you select the right zinc coating weight (G60 vs G90) to match your environmental requirements.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA