While iron-based PM is the “heavy lifter,” Copper-Based Powder Metallurgy is the functional expert. It excels in applications requiring electrical conductivity, thermal management, and self-lubrication.

| Material | Primary Benefit | Key Application |

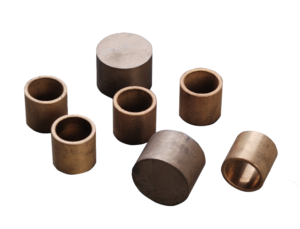

| Sintered Bronze | High porosity for oil retention | Self-lubricating bearings |

| Pure Copper | 90%+ IACS Electrical conductivity | Electrical contacts, heat sinks |

| Sintered Brass | Corrosion resistance & aesthetics | Decorative hardware, precision nuts |

Copper-based PM is the world’s leading technology for Oil-Impregnated Bearings.

The Structure: By controlling the pressing force, we create a metal matrix with 18%–25% interconnected pores.

The Mechanism: These pores are vacuum-filled with oil. When the shaft spins, friction heat draws the oil out; when it stops, the oil is re-absorbed.

Result: You get a mechanical component that remains lubricated for its entire service life without maintenance.

Zero Material Waste: Copper is expensive. Unlike CNC machining which turns 40% of the metal into scrap, PM uses 98% of the raw powder.

Precision & Quietness: Sintered copper parts have high damping capacity, making them run much quieter than solid steel gears or bushings in household electronics.

Net Shape: Complex flanges and spherical shapes are produced in a single stroke of the press, eliminating secondary labor.

Are you designing a small motor or a high-current connector? I can help you determine the ideal density to ensure your part maximizes conductivity while maintaining structural integrity.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA