Copper is a metal with extremely high ductility and excellent thermal and electrical conductivity, making it an indispensable material in the electronics, electrical, heat dissipation, and precision instrument fields. Its unique reddish-gold appearance, natural corrosion resistance, and superior processing characteristics give it a central position in high-end manufacturing.

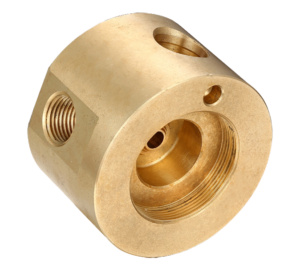

At Dewintech, we have extensive experience in copper processing. Addressing the high viscosity and thermal conductivity characteristics of pure copper (such as C1100 and C1010), we effectively solve heat dissipation and burr problems during processing through optimized CNC milling parameters, precision electrical discharge machining (EDM), and professional tool selection. Whether it’s complex conductive busbars, high-efficiency heat exchanger parts, or precision electronic contacts, Dewintech can provide you with high-precision, high-quality customized solutions.

| Property | Typical Value (C1xxx – C7xxx) | Unit |

| Electrical Conductivity | 25 – 101 | % IACS |

| Thermal Conductivity | 110 – 400 | W/m·K |

| Density | 8.80 – 8.96 | g/cm³ |

| Tensile Strength | 200 – 450 | MPa |

| Melting Point | 880 – 1083 | °C |

| Hardness | 40 – 150 | HV |

| Available Processes | CNC Machining, EDM, Cold Forging, Stamping | |

As your trusted partner for parts manufacturing, Dewintech offers the following core advantages in the field of copper materials:

Wide range of material grades: We support materials ranging from high-purity oxygen-free copper (OFC) to easy-to-machine tellurium copper, as well as various grades of brass and bronze. Dewintech engineers will provide the most professional selection advice based on your conductivity requirements and structural strength.

Strict tolerance control: Copper is prone to deformation during processing. Dewintech utilizes multi-axis machining centers and advanced fixture designs to ensure that parts maintain accuracy of ±0.01mm or even higher, even with complex geometries.

Targeted process optimization: Addressing the oxidation characteristics of copper, we offer a variety of surface treatment processes, including tin plating, nickel plating, silver plating, and anti-oxidation coatings, to ensure that parts maintain stable electrical performance even in harsh environments.

In-depth industry customization: From heat dissipation components for 5G base stations to precision fixtures for semiconductor packaging, Dewintech has solved countless copper processing challenges for global customers with its profound process expertise.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA