In the world of metal forming, Brass is the rare material that offers both high-end aesthetics and high-performance engineering. Composed primarily of copper and zinc, brass sheet is the premium choice for designers who refuse to compromise. It provides the electrical conductivity of copper, the strength of steel, and a natural antimicrobial surface—all wrapped in a timeless golden luster.

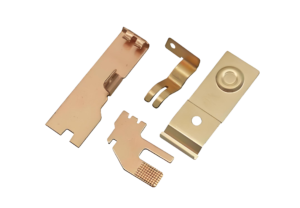

While other metals are hidden away, brass is often meant to be seen. From luxury interior hardware to precision electronic shielding, it brings a level of sophistication and reliability that few other alloys can match.

| Property | Typical Value | Unit | Why it Matters |

| Tensile Strength | 300 – 450 | MPa | High enough for structural integrity |

| Elongation | 15% – 45% | % | Allows for extreme deep-draw stamping |

| Electrical Conductivity | 28% | IACS | Ideal for terminals and connectors |

| Density | 8.53 | g/cm³ | Provides a premium, substantial feel |

| Melting Point | 915 | °C | Stable in high-heat environments |

| Forming Ability | Excellent | – | Minimal springback during bending |

Brass is remarkably “forgiving” in the press. Because of its high ductility, it can be stamped into complex, deep-drawn shapes (like shell casings or decorative bowls) without the risk of cracking common in harder metals.

During CNC bending, brass exhibits very low springback. This allows us to achieve incredibly sharp, tight-radius bends that remain dimensionally stable over time. Whether it’s a delicate contact spring for a circuit board or a heavy-duty architectural trim, the material holds its form with military precision.

Common Surface Finishes:

Mirror Polishing: Brings out the natural “gold” shine for high-visibility parts.

Clear Lacquering: Seals the surface to prevent the natural oxidation (tarnish) that occurs over time.

Antique Patina: For decorative projects, chemical aging can create a “vintage” bronze look.

Nickel or Gold Plating: Enhances conductivity and adds an extra layer of wear resistance.

Working with brass requires an artisan’s eye and an engineer’s precision. At Dewintech, we treat brass as more than just a metal—it’s a premium asset. Our stamping dies are polished to a mirror finish to ensure we don’t mar or scratch the delicate surface of the material during production.

We understand that for many of our clients, a brass part is the “face” of their product. Our team at Dewintech combines high-speed precision stamping with meticulous manual inspection, ensuring that every piece—from a tiny electrical terminal to a large decorative panel—is delivered with a flawless finish and exact tolerances.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA