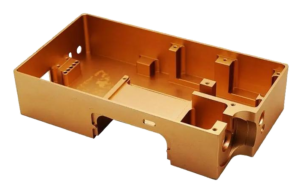

In the world of CNC machining, few materials command as much respect as Brass. Often referred to as the “Gold of Industry,” brass is much more than just a decorative alloy. It is a high-performance material that balances exceptional machinability with superior corrosion resistance and high electrical conductivity.

Whether it is for the intricate internal components of a luxury timepiece or the heavy-duty terminals in an electrical grid, brass delivers a unique combination of reliability and timeless aesthetic appeal.

The “Machining Speed Demon”: Brass is perhaps the most “forgiving” metal to machine. Its high cutting speeds and low tool wear allow for incredibly fast production cycles, making it the most cost-effective choice for high-volume precision parts.

Natural Antimicrobial Properties: Pure brass surfaces naturally kill bacteria and viruses, making it an essential material for medical devices and high-touch public hardware.

Low Friction & Spark Resistance: Brass is inherently “self-lubricating” compared to steel, making it ideal for gears, bearings, and valves where friction must be minimized and safety is paramount.

Exquisite Aesthetics: No other industrial metal offers the warm, premium golden hue of brass, which can be polished to a mirror finish or aged for a vintage look.

| Property | Typical Value | Unit |

| Machinability Rating | 100 (Industry Benchmark) | % |

| Tensile Strength | 330 – 550 | MPa |

| Electrical Conductivity | 25 – 28 | % IACS |

| Density | 8.4 – 8.7 | g/cm³ |

| Thermal Conductivity | 115 – 120 | W/m·K |

| Melting Point | 885 – 930 | °C |

| Hardness | 70 – 160 | HB |

Primary CNC Processes:

High-Speed Turning: Ideal for fasteners, pipe fittings, and nozzles.

5-Axis Milling: For complex musical instrument parts, luxury hardware, and intricate heat sinks.

Precision Threading: Because brass is soft yet strong, it produces the cleanest, most durable threads in the industry.

Common Applications:

Electronics: Connectors, terminals, and RF shielding.

Fluid Control: Valve bodies, pump impellers, and hydraulic fittings.

Architecture & Design: Door handles, luxury lighting components, and high-end automotive trim.

Surface Treatment Options:

Mirror Polishing: To achieve a high-end jewelry-like finish.

Passivation: To enhance natural corrosion resistance without changing the color.

Electroplating: Frequently plated with Chrome, Nickel, or 24K Gold for specific industrial or luxury requirements.

Clear Coating/Lacquering: To prevent natural oxidation (tarnishing) and maintain the golden shine.

Precision in brass requires more than just high-speed spindles; it requires an eye for detail. At Dewintech, we treat every brass component—whether it’s a rugged industrial connector or a decorative enclosure—with the same rigorous standards of excellence.

Our specialized CNC tooling is calibrated specifically for brass alloys like C36000 (Free Cutting Brass) and C46400 (Naval Brass) to ensure burr-free edges and a superior surface finish straight off the machine. With Dewintech’s integrated quality control and custom surface treatment capabilities, we provide a seamless “Design-to-Delivery” experience that honors both the technical and aesthetic demands of your project.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA