Aluminum sheet is one of the most commonly used materials in stamping and bending applications, valued for its light weight, excellent formability, and corrosion resistance. Compared with steel, aluminum can be formed with lower force, making it highly suitable for high-efficiency sheet metal production.

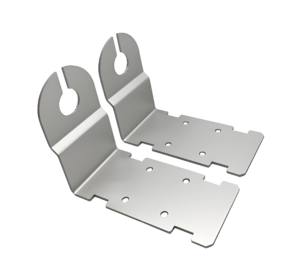

At Dewintech, aluminum sheet is widely applied in structural panels, enclosures, brackets, and custom formed parts, especially where weight reduction and clean appearance are required.

Excellent Formability

Aluminum alloys such as 5052 and 3003 can withstand deep drawing and repeated bending with minimal cracking.

Lightweight Strength

Only about one-third the weight of steel, aluminum helps reduce overall product weight without sacrificing structural integrity.

Natural Corrosion Resistance

The oxide layer provides protection against oxidation, suitable for indoor and outdoor applications.

Good Surface Quality

Smooth surfaces are ideal for anodizing, painting, and powder coating after forming.

Electrical enclosures · Panels & covers · Brackets · Heat shields · Automotive & industrial sheet parts

| Property | Typical Range | Unit |

| Density | 2.68 – 2.72 | g/cm³ |

| Tensile Strength | 110 – 290 | MPa |

| Elongation | 8 – 25 | % |

| Available Thickness | 0.5 mm – 6.0 mm (Typical) | |

We control bend radius, spring-back, and flatness through optimized tooling and forming parameters, ensuring stable dimensions and clean edges for aluminum stamped and bent parts.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA