Aluminum is a silvery-white light metal and one of the most widely used metal materials in industry today. Due to its excellent strength-to-weight ratio, superior corrosion resistance, and excellent thermal and electrical conductivity, aluminum is the material of choice for aerospace, automotive manufacturing, electronics, medical equipment, and precision machinery components.

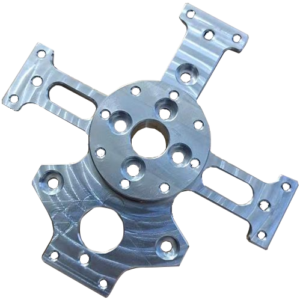

At Dewintech, we have years of experience in aluminum alloy processing. Whether it’s high-precision CNC milling/turning or large-scale production of aluminum die casting and extrusion, Dewintech can provide you with a one-stop solution from raw material selection to surface treatment (such as anodizing and hard anodizing). Through our rigorous quality control system, we ensure that every aluminum part delivered meets your tolerance requirements and performance standards.

Extremely lightweight: With a density only one-third that of steel, it’s the ideal choice for achieving structural weight reduction.

Easy machinability: Aluminum has excellent cutting properties, significantly shortening processing cycles on Dewintech’s production lines and reducing your procurement costs.

Superior surface treatment: Easily anodized, powder coated, or electroplated, offering a wide range of color options and improved wear resistance.

Sustainability: 100% recyclable, meeting the requirements of modern manufacturing for environmental protection and green energy.

| Property | Typical Value (1xxx – 7xxx) | Unit |

| Tensile Strength | 70 – 600 | MPa |

| Yield Strength | 30 – 500 | MPa |

| Density | 2.63 – 2.85 | g/cm³ |

| Thermal Conductivity | 120 – 230 | W/m·K |

| Elastic Modulus | 68 – 72 | GPa |

| Melting Point | 580 – 660 | °C |

| Available Processes | CNC Machining, Die Casting, Extrusion, Stamping | |

As a professional parts processing partner, Dewintech provides not only materials but also comprehensive technical support:

Material Consultation and Selection: Our engineering team will recommend the most suitable alloy grade based on your application scenarios (such as high strength, high heat dissipation, or decorative requirements), such as 6061, 7075, 5052, or die-casting grade ADC12.

Extreme Precision Tolerances: Relying on advanced five-axis CNC equipment and automated production lines, we can consistently control the processing accuracy of aluminum parts within ±0.005mm.

Excellent Surface Treatment: Aluminum is easily anodized, powder coated, or sandblasted. Dewintech offers a wide range of color options, enhancing both the appearance and wear resistance of the parts.

Experience in Multiple Fields: Whether it’s precision electronic enclosures, complex automotive structural components, or medical device brackets, Dewintech has mature mass production cases and a rigorous quality traceability system.

Contact us to evaluate manufacturability, tolerances, and cost for your specific application.

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA