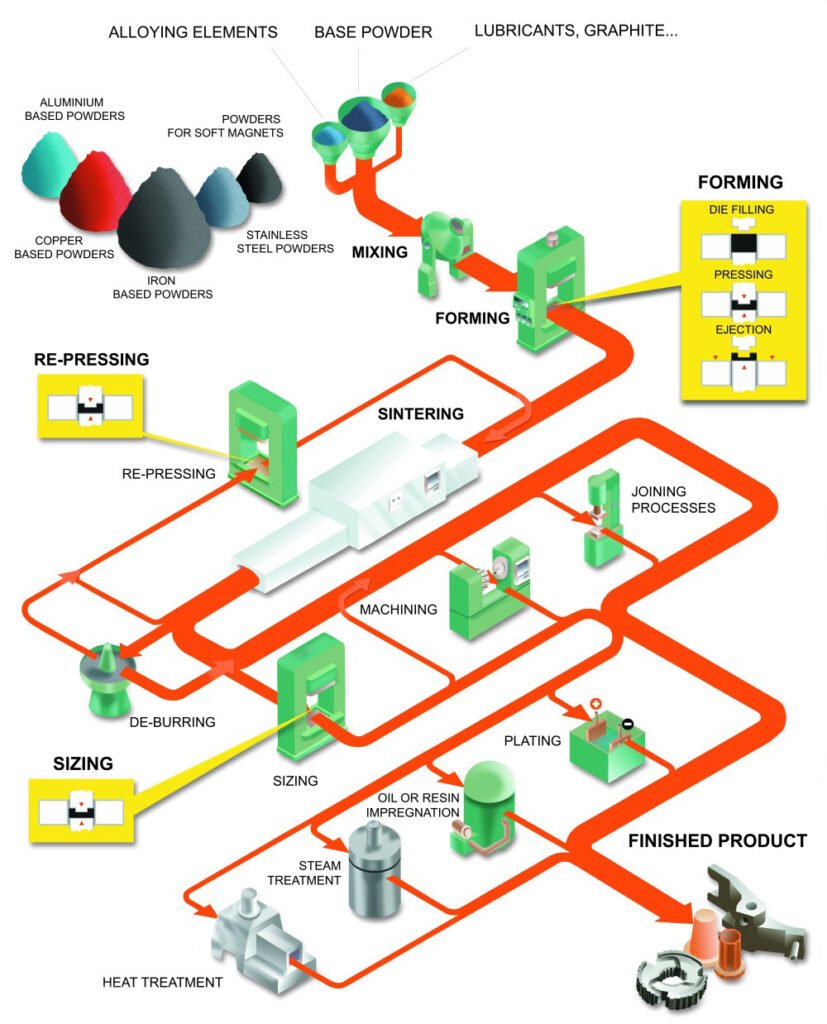

The main steps of the powder metallurgy process are raw material mixing, pressing, sintering and post-processing. Among them, sintering is the most important and critical step in the powder metallurgy process. Why?

In the production of powder metallurgy products, the sintering process is a key step in converting the product from a blank to a semi-finished product, and then it is post-processed to form a finished product. Powder metallurgy production has the advantage of a short production period, but it also creates the disadvantage of unstable structure.

Through the sintering process, during the high-temperature heating process, we can further increase the strength and density of the product structure and improve the stability of the physical properties of the product.

Will the product deform after sintering? Will the product reduce porosity after sintering? Will the product change density after sintering? For such problems, we can deeply check the quality of the products in the sintering process.

Therefore, it can be found that the sintering process actually plays an important role in the entire powder metallurgy process. Through sintering, the product performance can be further improved, and the necessary strength can be provided for post-processing. The importance of the sintering process is also evident.