Aluminum. Zinc. Magnesium.

Each alloy offers unique strengths.

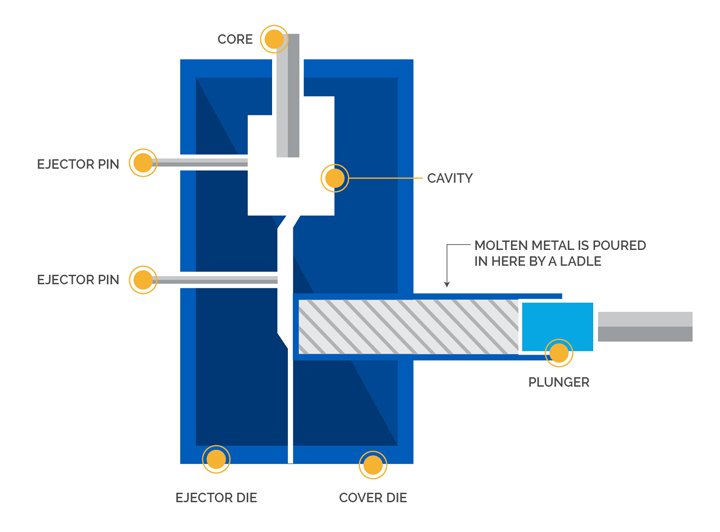

Sand casting.

Investment casting.

High and low pressure die casting.

No need to worry about the technical details.

Just let Dewin know your requirements —

we’ll handle the rest, from sourcing to delivery.

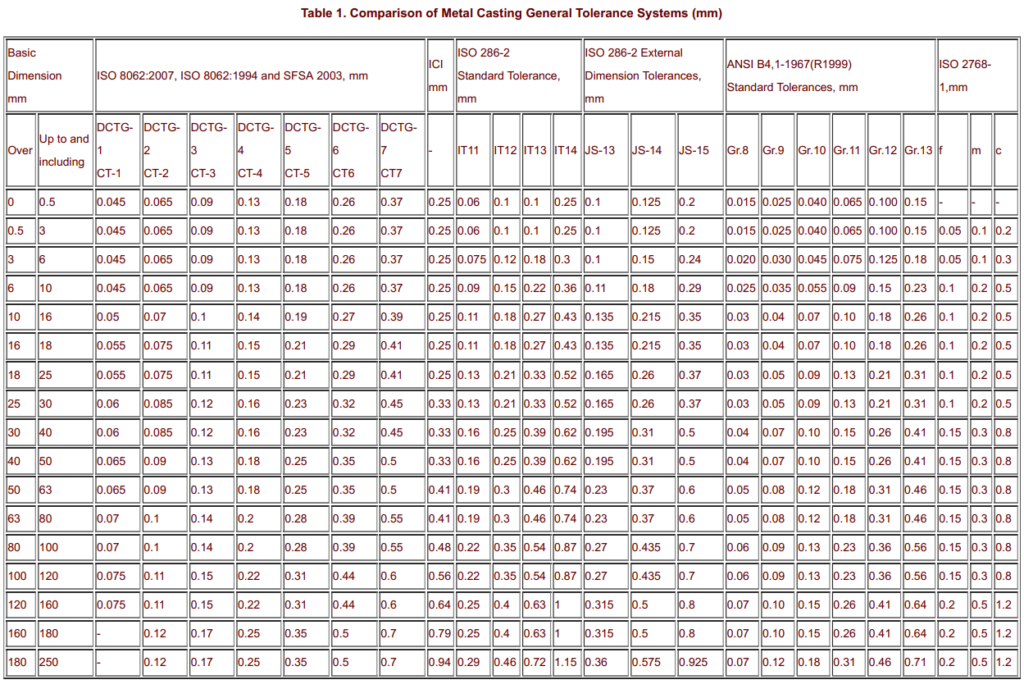

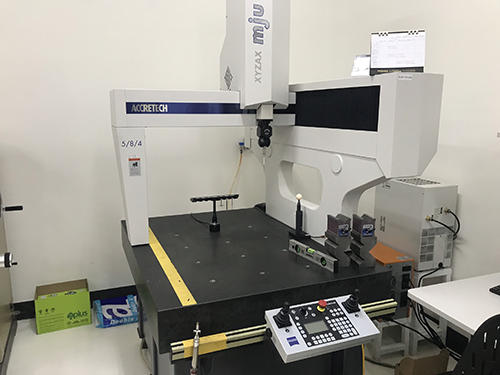

| Factory Code | Location | Established | Number of Workers | Floor Area (m²) | Min tolerance of precise machining | Certification | General lead time | Most competitive products |

|---|---|---|---|---|---|---|---|---|

| DWS2025657 | Binh Duong | 2019 | 45 | 5000 | 0.02 mm | ISO 9001:2015 | Tooling 30 days, Sample 7 days, Batch 30->60 days. | U55X inner link driver, P558 upper mount idler, 19DT upper mount idler, T1XX upper mout idler. |

| DWS2025658 | Binh Duong | 2014 | 54 | 25000 | / | ISO 9001:2015 | Tooling 50 days, Sample 7 days, Batch 30 days. | UL Listed, Connection/Suction |

| DWS2025659 | Long An | 2007 | 463 | 60000 | 0.01 mm | / | Tooling 60 days, Sample 7 days, Batch 30 days. | Aluminum and copper casting parts, Houseware (cooker, furnace bar) |

| DWS2025660 | Long An | 2021 | 131 | 15000 | ISO 2768-mk | ISO 9001:2015 | Tooling 45 days, Sample 20 days, Batch 30 days. | Die casting components for gas system, car. |

| DWS2025661 | Binh Duong | 2016 | 17 | 1500 | 0.1mm (DIN ISO 2768 for normal dimension) | / | Tooling 45 days, Sample 7 days, Batch 30 days. | Aluminum die-casting components |

| DWS2025662 | Dong Nai | 2011 | 39 | 5000 | ISO 2768-mk | ISO 9001:2015 | Tooling 30 days, Sample 20 days, Batch 30 days. | Gas stove parts, parts in motorbikes |

| DWS2025663 | Dong Nai | 2020 | 145 | 5000 | 0.05 mm | / | Tooling 45 days, Sample 30 days, Batch 60 days. | Aluminum Die Casting, Extrusion |

| DWS2025664 | Ho Chi Minh | 2004 | 50 | 2485 | 0.02 mm | ISO 9001:2015 | Tooling 60 days, Sample 7 days, Batch 30->60 days. | Machine components, Clothes horse |

| DWS2025665 | Dong Nai | 2008 | 35 | 2500 | ISO 2768-mk | / | Tooling 30 days, Sample 30 days, Batch 30 days. | Fire protection components |

| DWS2025666 | Da Nang | 2013 | 18 | 3000 | ISO 8062-mk | ISO 9001:2015 | Tooling 30 days, Sample 10 days, Batch 30 days. | Iron sand casting products |

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA