Unique properties provided by a wide range of Aluminum, Zinc and Magnesium alloys

Sand casting

Investment casting

Lost wax casting

High pressure casting, Low pressure casting …

You don’t have to know all these shit, just tell your ideas to Dewin team

| Possible weight of the part | 0.015 ~ 12 kgs |

| Possible size of the part | 4 mm ~ 650 mm |

| Possible wall thickness | 0.3 mm ~ 13 mm |

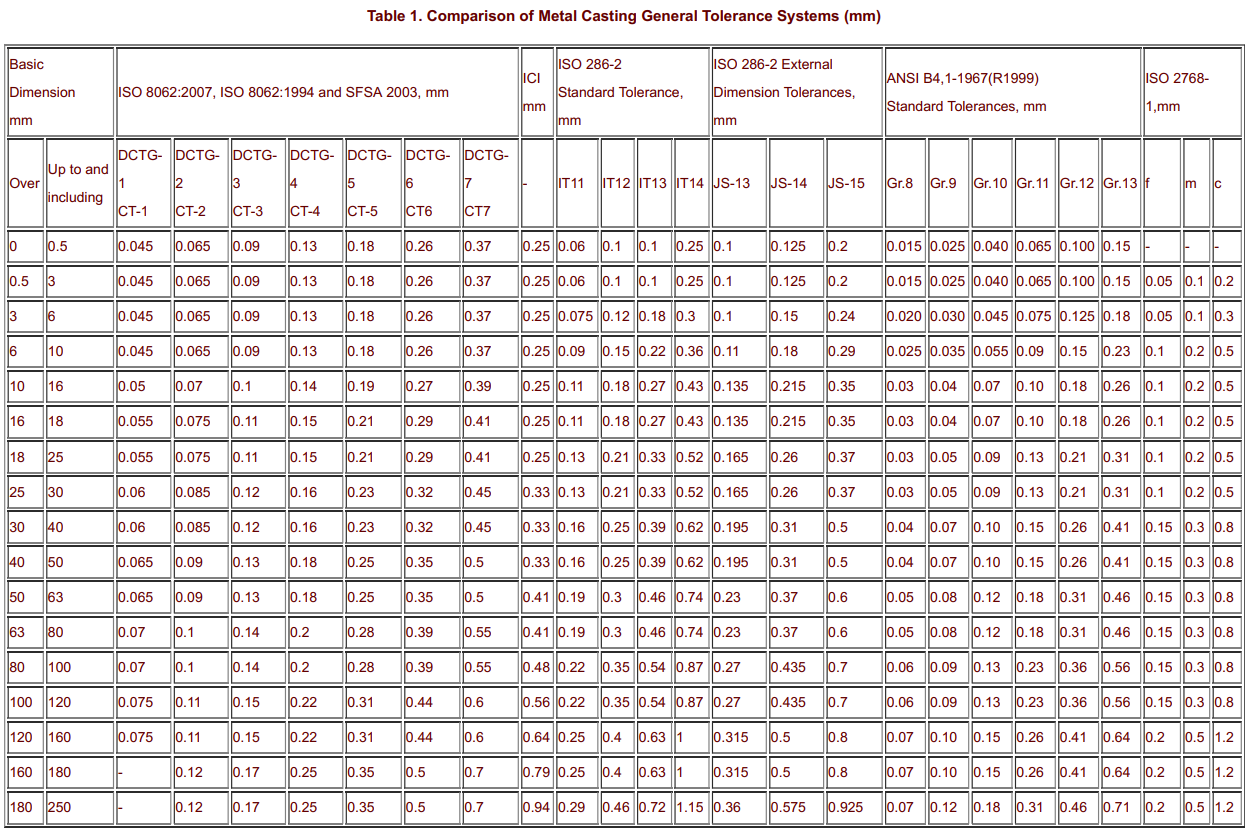

| Tolerances by casting | ± 0.1 mm |

| Tolerances by post machining | 0.02 mm |

| Minimum order quantity | 500 kgs |

We will contact you within 1 working day, please pay attention to the email with the suffix “@dewintech.com”.

Your privacy is safe, we won’t use your email for any other purposes.