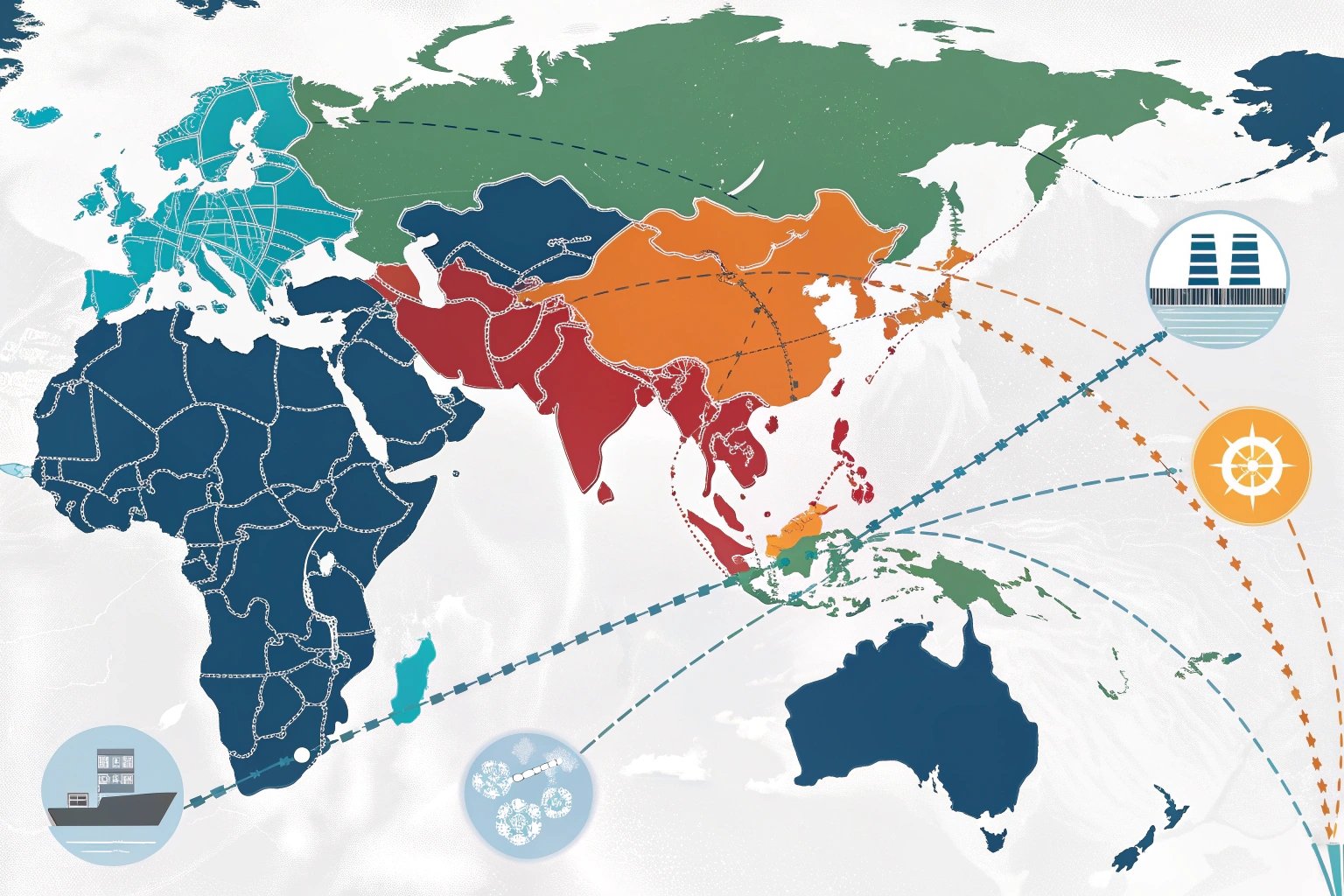

If you are considering moving your supply chain out of China, you're not alone. With global trade tensions and rising costs, many businesses are exploring alternatives. But how do you choose the right country for your new supply chain?

The best alternative to China largely depends on your needs. Vietnam has become a top choice due to its proximity, low labor costs, and favorable trade agreements1. However, several factors—such as logistics, infrastructure, and political stability—should influence your decision.

Before jumping into any conclusions, it’s important to evaluate a variety of countries based on specific factors such as cost, infrastructure, labor force, and ease of communication. Let’s explore some key alternatives and their advantages and disadvantages for businesses considering relocating their supply chains.

What should I pay attention to when I move the supply chain out of China?

Moving a supply chain out of China can seem like a straightforward task. However, it’s crucial to understand the underlying factors that can make or break your decision.

While it may seem tempting to relocate your supply chain for cost savings, you must consider factors like logistics, supplier relationships, quality control, and new supplier training2. These elements can impact the overall transition cost and time.

When relocating your supply chain, one of the first things to consider is the potential cost of transitioning. Many businesses overlook the cost of relocating molds or tooling used in manufacturing3. If you’ve already had molds created with your Chinese suppliers, be aware that they may charge significant fees (up to 50% more) to relocate these tools to another country.

Additionally, transitioning to a new supplier involves hidden costs like re-training your team and developing new communication methods. Working with a supplier in a different culture or time zone often requires a steep learning curve. Moreover, the shipping and logistics costs from your new manufacturing country to your target market could be higher than anticipated, especially if the country lacks well-established trade routes.

For instance, in the case of countries like India or Indonesia, where infrastructure may not be as advanced as China’s, delays in shipments could lead to missed deadlines and higher costs. Similarly, the political stability and business environment of the country you’re moving to should be factored in. Some countries offer tax incentives and free trade agreements, which could help lower your total cost. But keep in mind that navigating local regulations may be time-consuming and sometimes even frustrating.

In summary, when planning to move your supply chain, ensure you understand all associated costs—not just the product unit price. Consider logistics, the cost of moving or re-making molds, training new suppliers, and potential communication barriers. Even seemingly small changes can accumulate into significant costs over time.

Will the cost be lower if my supply chain is moved out of China?

Cost savings are often the primary driver for relocating supply chains, but will you really save money by moving production out of China?

While you may expect cost savings, this isn't always the case. Factors like labor costs4, tariffs, logistics5, and supply chain reliability will impact your final costs. Countries like Vietnam and Mexico might offer lower direct manufacturing costs, but the hidden expenses can add up.

Comparison of Labor Costs and Other Key Factors

| Country | Labor Cost (per hour) | Logistics | Supply Chain Readiness | Infrastructure | Trade Agreements |

|---|---|---|---|---|---|

| Vietnam | $2 - $3 | Developing | Strong for labor-intensive work | Improving ports and roads | Free Trade Agreements (CPTPP, EVFTA) |

| India | $1.50 - $2 | Challenging | Developing, varies by region | Poor in some areas | Make in India program |

| Mexico | $3 - $5 | Excellent | Strong in automotive parts | Good for most industries | USMCA with the USA & Canada |

| Thailand | $3 - $5 | Growing | Good for automotive and electronics | Improving | ASEAN trade agreements6 |

| Indonesia | $1.50 - $2.50 | Challenging | Developing, less reliable | Moderate | Preferential tariffs for ASEAN markets |

Moving your supply chain away from China can lead to cost savings, but the overall financial impact depends on several factors. A country like Vietnam, for example, has lower labor costs compared to China, especially when compared to China’s coastal regions. This might initially look like a clear advantage for businesses seeking to cut down on production costs. However, the full picture involves more than just labor costs.

In countries like Vietnam, the manufacturing infrastructure may still be developing, particularly in industries requiring high precision or advanced technology. This could result in a need to invest in additional training for local workers or upgrading machinery to match the standards you're used to. Even if the unit price is lower, these investments could offset any immediate savings you expect to gain.

Comparing Logistics and Trade Agreements

| Country | Shipping to the US | Trade Agreement | Customs and Duties | Customs Efficiency |

|---|---|---|---|---|

| Vietnam | 15-20 days | CPTPP, EVFTA | Low, few tariffs | Moderate |

| India | 20-30 days | Few agreements | High duties | Moderate |

| Mexico | 5-10 days | USMCA | Very low | Excellent |

| Thailand | 15-20 days | ASEAN | Moderate | Good |

| Indonesia | 20-30 days | ASEAN | Moderate | Poor |

In contrast, countries like Mexico, which are closer to the US market, can offer significant logistics savings. With a favorable trade agreement like the USMCA, your business may benefit from reduced tariffs when exporting goods to the US, making the overall cost of production lower despite slightly higher labor costs compared to Southeast Asia.

Moreover, political risks and the stability of a country’s manufacturing environment play a crucial role. Countries with more stable political environments—such as Vietnam, Thailand, or Mexico—tend to offer a more predictable business environment, which can reduce risks associated with supply chain disruptions.

In the end, while moving your supply chain out of China may offer some savings, the full financial picture includes factors beyond raw labor cost. Logistics, infrastructure, and political stability must also be considered to determine whether it will truly result in lower costs for your business.

Conclusion

When moving your supply chain, it's crucial to look beyond immediate cost savings. Consider all the hidden costs involved to determine if relocation is truly beneficial.

Explore why Vietnam's proximity, low labor costs, and favorable trade agreements make it a leading alternative for supply chain relocation. ↩

Understand the critical factors such as logistics, supplier relationships, and quality control that impact the success of supply chain relocation. ↩

Learn about the significant costs and considerations involved in relocating molds or tooling, a crucial aspect of manufacturing supply chain relocation. ↩

Understanding labor costs is crucial for businesses considering relocating their supply chain to ensure cost-effectiveness. ↩

Logistics efficiency can significantly impact the overall cost and reliability of your supply chain. ↩

Trade agreements can offer competitive advantages, such as reduced tariffs and improved market access, essential for strategic planning. ↩