I once received three different quotes for the same part—just because I didn’t send the right technical files upfront.

To get accurate quotes from Vietnamese suppliers, you must send 2D and 3D drawings, tolerances, material specs, finish details, quantity info, and inspection expectations—all clearly defined.

Without these, factories will either guess or walk away. Let’s fix that.

What drawing format and tolerances should you send?

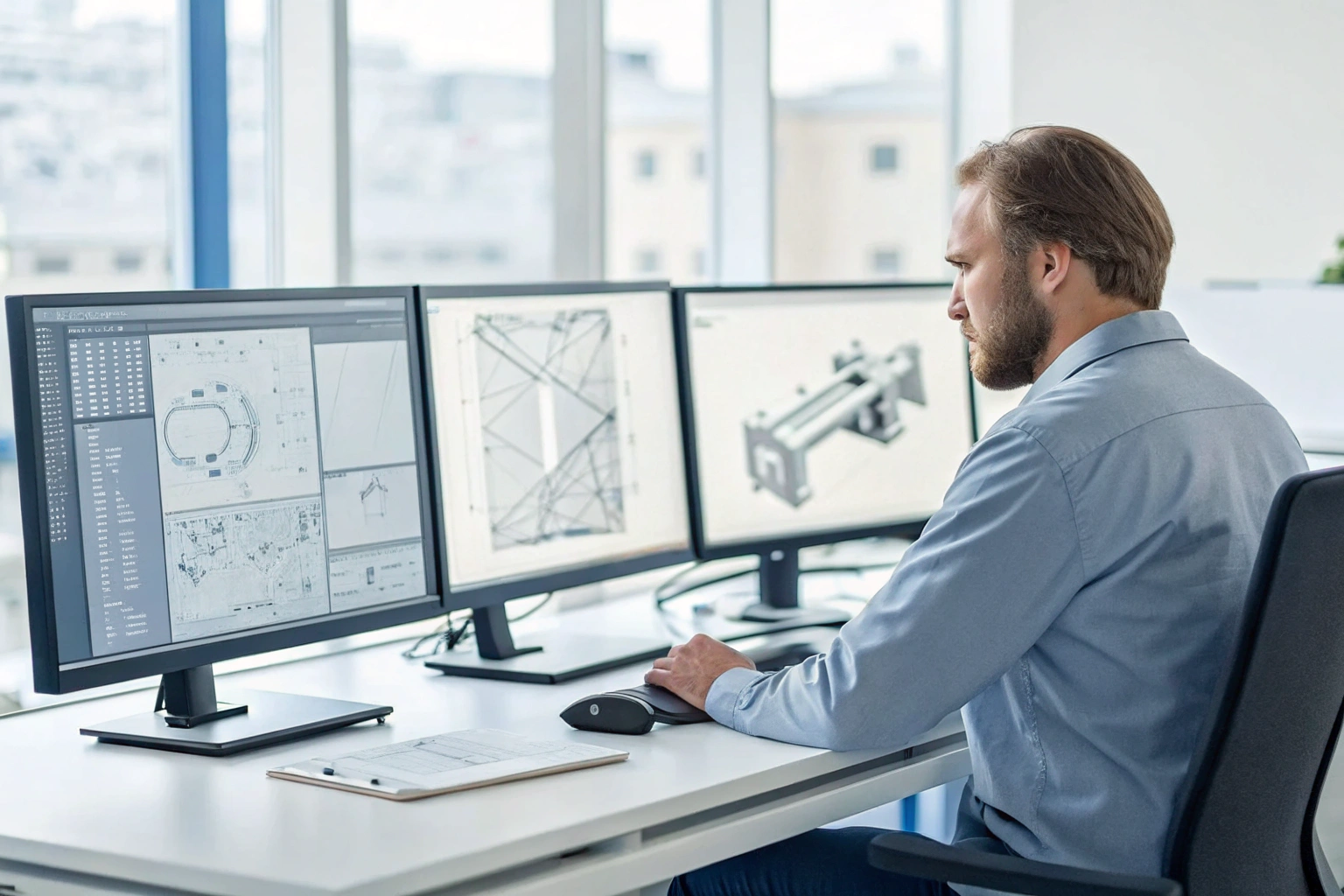

A supplier once told me they couldn’t quote unless I gave them a STEP file. That’s when I realized 2D alone wasn’t enough.

Send both 2D drawings (with full dimensions and tolerances) and 3D models (STEP or IGES format). Clearly define critical tolerances using GD&T.

Providing both 2D and 3D gives Vietnamese suppliers the full picture. The 2D tells them how to inspect. The 3D helps them calculate tooling and CNC paths. Without both, they risk misquoting.

For more clarity on 3D modeling standards, see ISO 10303 STEP format guide 1.

Recommended File Types

| File Type | Format Examples | Purpose |

|---|---|---|

| 2D Drawing | PDF, DWG, DXF | Dimension & tolerance communication |

| 3D Model | STEP (.stp), IGES (.igs), SLDPRT | Mold design, machining, simulation |

| BOM & Notes | Excel, TXT | Supplementary instructions, specs |

What Tolerances to Define

- Linear (e.g., ±0.05 mm)

- Angular (e.g., ±1°)

- Position, flatness, concentricity (using GD&T)

- Surface roughness (e.g., Ra 1.6 µm)

Also identify critical-to-function dimensions. Use section views for internal features. Add datums and hole tables if needed. Clarity here saves you money later.

To better apply geometric tolerances, refer to ASME Y14.5 GD&T standard 2.

Do you need material spec and certificate?

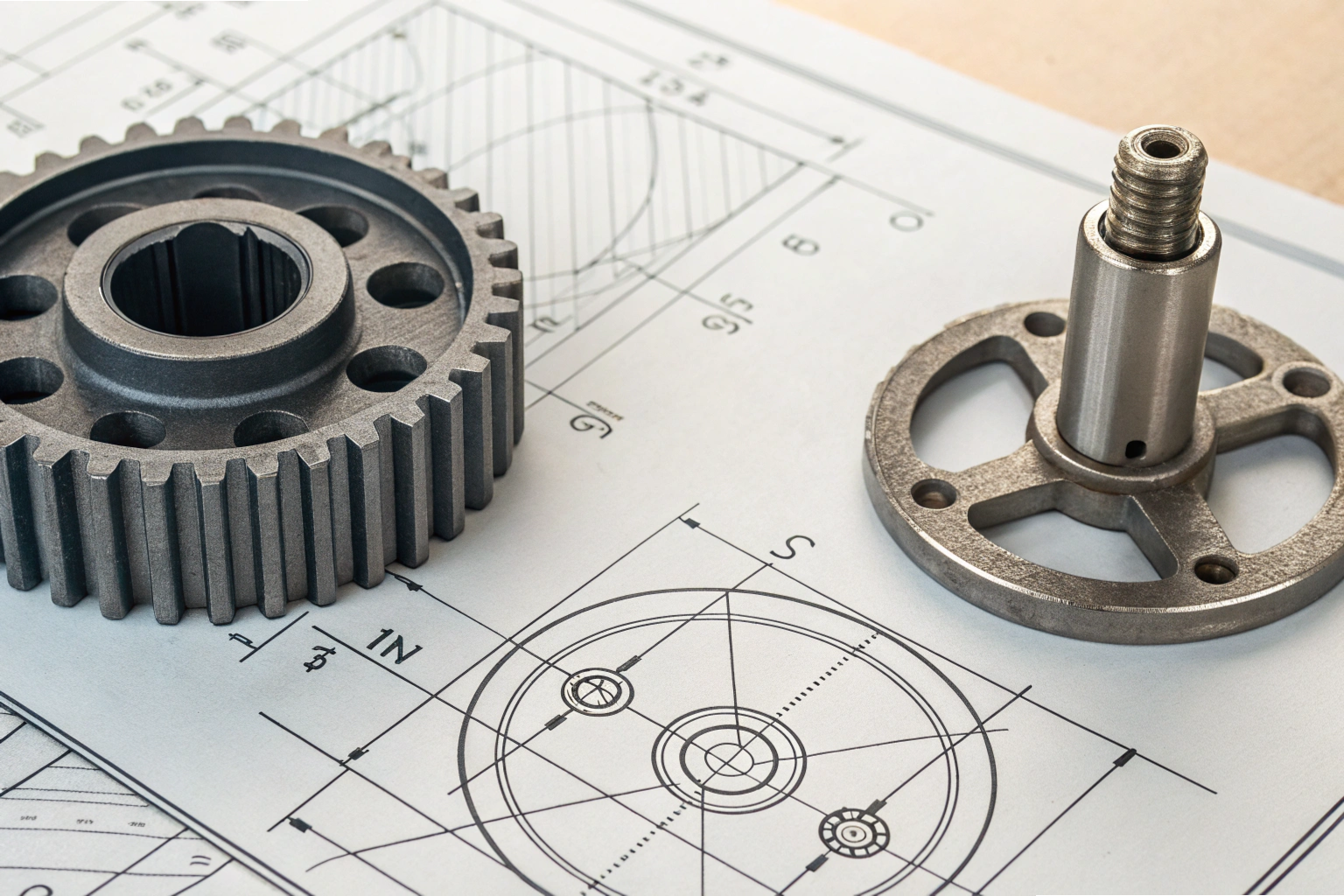

I once asked for stainless steel—only to get a grade that corroded after 3 weeks. That mistake taught me to always list the exact spec.

Yes, you must provide exact material grade, condition (e.g., hardened or annealed), and required certificate (e.g., EN10204 3.1).

Vietnamese suppliers are familiar with U.S. and Japanese standards. If you use EU or China standards, give an equivalent or include a conversion chart.

For European buyers, EN 10204 certification types 3 are essential for traceability.

Key Material Info to Include

| Requirement | Example |

|---|---|

| Grade + Spec | 6061-T6 Aluminum, ASTM B221 |

| Condition | Fully annealed or Q&T |

| Mechanical Property | Yield ≥ 250 MPa |

| Mill Cert Required? | Yes – EN10204 3.1 |

| Corrosion Resistance | Must pass 96hr salt spray |

| Substitution Allowed? | No – exact match only |

If you don’t provide this, suppliers may choose cheaper substitutes. Worse, they may use uncertified material that fails your end-use. Always list if test reports are required.

Pro tip: add a note saying “no substitution without written approval.” That one line can save you thousands in recall costs. For reference, check ASTM B221 standard for aluminum extrusions 4.

Should you include surface finish and post-treatment?

I once forgot to mention anodizing. The supplier shipped raw aluminum parts that failed cosmetic tests on arrival.

Yes, list all surface finishes (e.g., anodizing, powder coating) and machining finishes (e.g., Ra 0.8 µm). Add post-processes like heat treatment or polishing.

Finish affects pricing, timing, and vendor selection. It also impacts how the part performs—especially for corrosion resistance or tight fits.

To choose finishes properly, see MIL-A-8625 anodizing specification 5.

Common Surface Treatments and Their Specs

| Process | Example Spec | Why It Matters |

|---|---|---|

| Anodizing | Type II, Black, 25 µm | Aesthetic + corrosion resistance |

| Powder Coat | RAL 9005, 60 µm | Cosmetic + impact resistance |

| Electroplating | Zinc, 10 µm, yellow chromate | Salt-spray performance |

| Passivation | Nitric acid method, ASTM A967 | Stainless steel protection |

| Ra Finish | Ra 1.6 µm on mating surface | Surface fit, seal performance |

You can review ASTM A967 passivation standards 6 to ensure stainless steel protection compliance.

For complex parts, list process sequence like this:

Machining → Deburring → Heat Treat → Grinding → Anodize → Laser Mark

Also specify if masking is needed during surface treatment. E.g., “Do not anodize mating surface Ø12.00 mm ±0.02.”

Miss this step, and you risk rework delays or function failure.

How to define quantity and batch size clearly?

I’ve seen quotes swing 30% just because I didn’t mention batch size. Suppliers need it to price tooling, plan labor, and schedule machines.

You must list initial quantity, future forecast, and production batch size (e.g., 200 pcs per batch, 2,000 pcs per year).

The more precise you are, the better pricing you’ll get. Vagueness leads to padded estimates.

For better batch planning, see lean manufacturing principles 7 and EOQ economic order quantity models 8.

Quantity Breakdown Table

| Description | Quantity | Frequency |

|---|---|---|

| First order (prototype) | 50 pcs | Once |

| Regular order batch | 200 pcs | Quarterly |

| Annual volume forecast | 800 pcs | Per year |

| Lifetime estimate | 4,000 pcs | 5 years |

Also clarify:

- Is tooling amortized or paid upfront?

- Will batches be released evenly or seasonally?

- Can partial shipments be accepted?

- Is quantity fixed or flexible within ±10%?

For example:

"Annual forecast: 2,000 pcs. Order in batches of 250 pcs. Delivery every 6 weeks. Accept ±5% tolerance on quantity. Tooling amortized over 4 orders."

This clarity reduces misunderstandings and lets suppliers optimize production—lowering your cost per part. For international shipments, consult Incoterms 2020 guide 9 for delivery term consistency.

Conclusion

For accurate quotes from Vietnamese factories, your RFQ must include complete drawings, tolerance details, material specs, surface finish instructions, clear quantities, and batch size info.

Each omission leads to guesswork—and guesswork costs you time and money. Get specific, stay in control. For supplier evaluation tips, review ISO 9001 supplier quality management guidelines 10.

Footnotes

1. ISO STEP file format reference for CAD/CAM data exchange. ↩︎

2. Official ASME Y14.5 GD&T standard reference. ↩︎

3. Overview of EN 10204 material certificate types. ↩︎

4. ASTM B221 aluminum extrusion specification details. ↩︎

5. MIL-A-8625 anodizing specification for aluminum finishes. ↩︎

6. ASTM A967 passivation requirements for stainless steel. ↩︎

7. Introduction to Lean manufacturing fundamentals. ↩︎

8. EOQ model for optimizing order quantities. ↩︎

9. ICC guide on Incoterms 2020 for global trade. ↩︎

10. ISO 9001 supplier quality management framework. ↩︎