Understanding the pricing of customized metal parts is essential for businesses looking to manage costs effectively. The cost of custom parts is influenced by various factors, from design complexity to order volume. When sourcing customized parts, knowing these elements can help you make informed decisions, avoid surprises, and ensure your budget aligns with your needs.

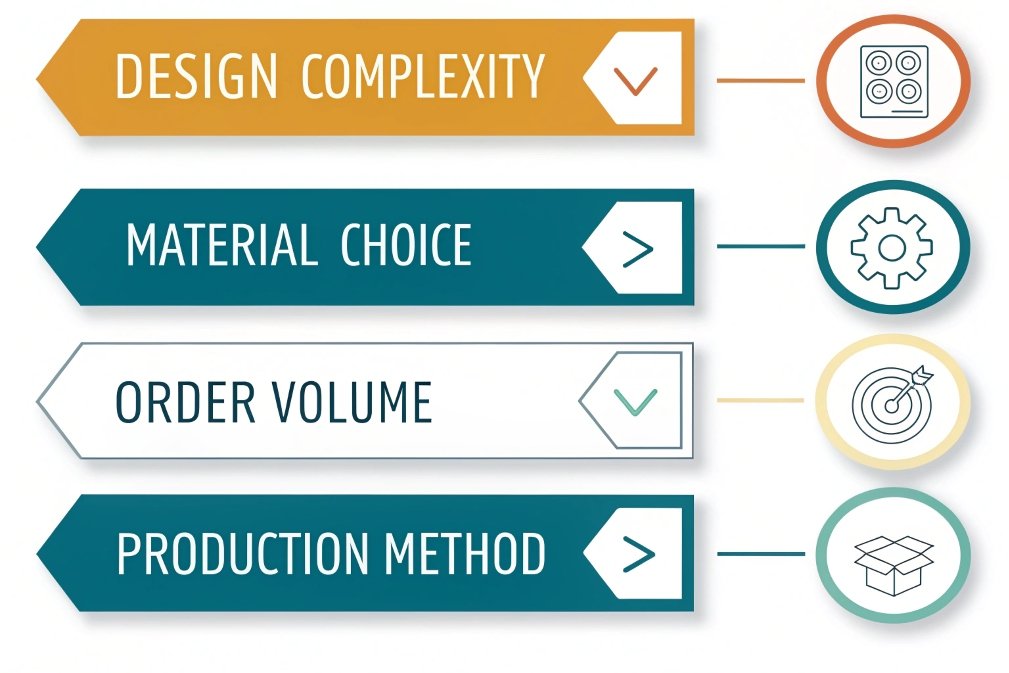

The pricing of customized metal parts is determined by several factors such as complexity, materials, order volume, and production methods. Understanding these factors can help businesses optimize their costs while meeting their manufacturing requirements.

In this article, we’ll break down how each of these factors affects pricing, and why understanding them is crucial for businesses sourcing customized parts.

How Does the Complexity of Custom Parts Influence Pricing?

The complexity of custom parts1 has a direct impact on pricing. More intricate designs require specialized tooling, more labor, and longer production times, which increases the overall cost.

When ordering customized metal parts, the complexity of the design plays a significant role in determining the price. Simple parts with basic shapes and minimal features tend to be less expensive to produce, while intricate or highly customized designs will increase production costs. Here’s why:

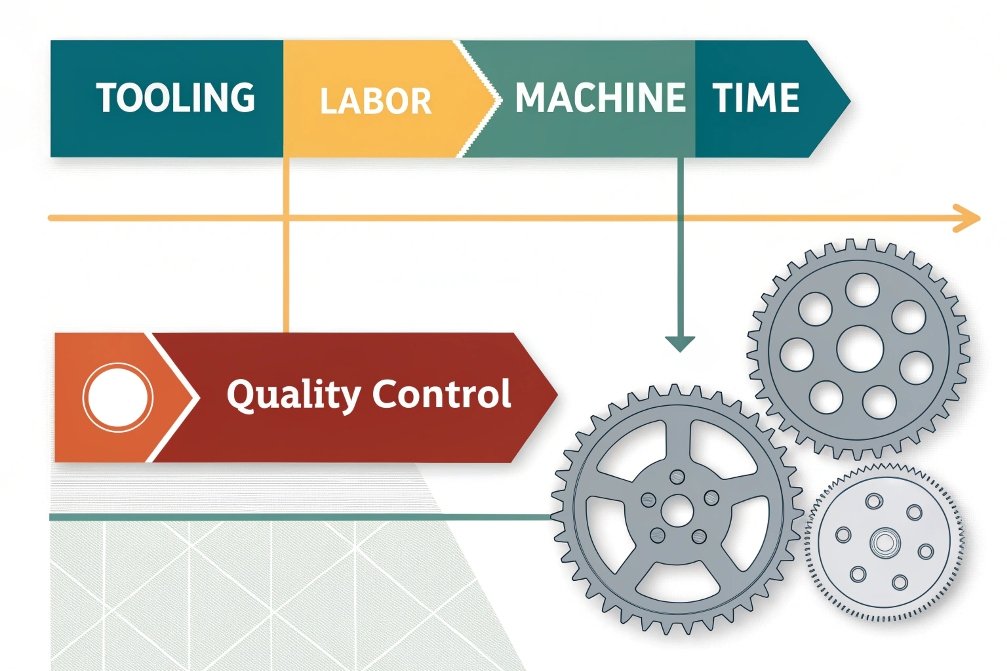

1. Tooling and Equipment Costs2

Complex parts often require specialized molds, tools, or machines to be created. The more intricate the part, the higher the investment in tooling, which can drive up the price.

- Simple parts require standard tooling, which lowers costs.

- Complex parts may need unique molds, adding to initial costs.

2. Longer Production Time3

Complex custom parts often take longer to manufacture due to their design and the need for precise fabrication. As production time increases, so do labor costs and machine operating costs.

- The more detailed the design, the longer it takes to produce.

- Longer production times lead to higher labor and operational costs.

3. Higher Precision and Quality Control

Intricate parts often demand a higher level of precision, which means stricter quality control processes. This leads to additional steps during production and can increase inspection time.

- More complex designs require higher precision and detailed inspections.

- Stringent quality checks raise overall production costs.

| Complexity Factor | Description | Impact on Pricing |

|---|---|---|

| Tooling and Equipment | Complex parts need specialized molds and tools | Increases initial production costs |

| Production Time | Longer production cycles for intricate parts | Leads to higher labor costs and machine usage |

| Precision and Quality Control | More detailed inspection and precision needed | Adds additional steps and costs to the production process |

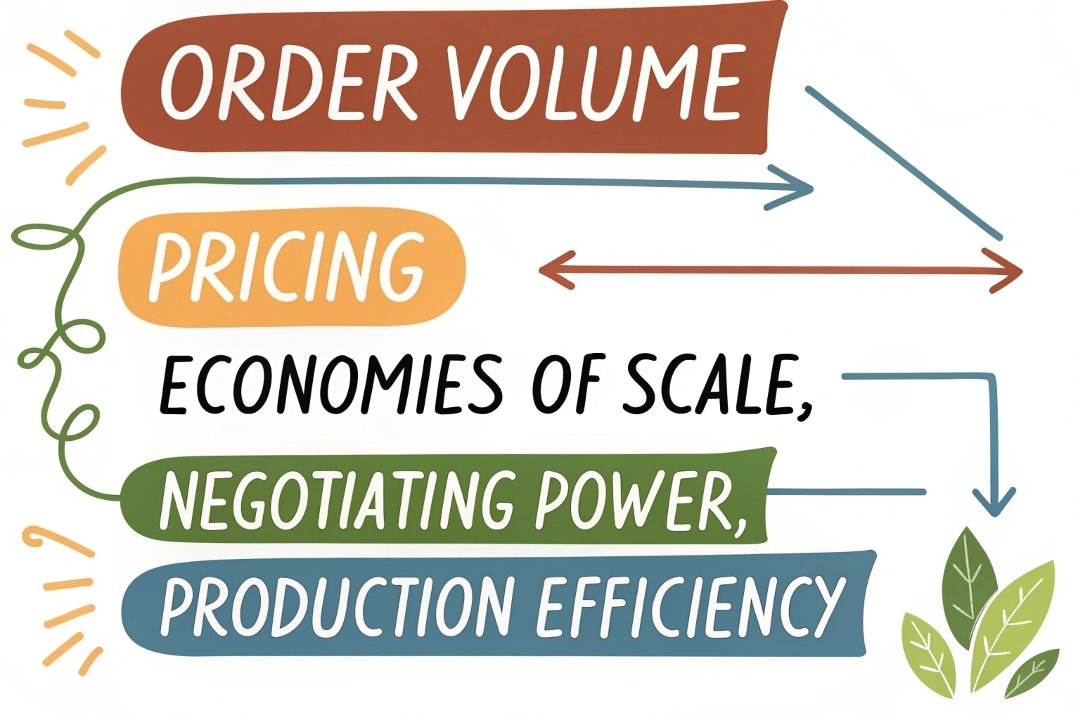

What Role Does Order Volume Play in the Pricing of Custom Parts?

Order volume plays a significant role in the cost structure of customized metal parts. Larger orders generally lead to lower unit costs, thanks to economies of scale.

When it comes to customized metal parts, order volume has a significant impact on pricing. Here’s how:

1. Economies of Scale

For larger orders, the cost per unit typically decreases because the setup costs (tooling, production planning, etc.) are spread over more units. This leads to a lower price per unit as the manufacturer can distribute fixed costs across a larger number of parts.

- Bulk orders spread tooling and setup costs, reducing per-unit cost.

- Smaller orders don’t benefit from this spread, so per-unit costs are higher.

2. Negotiating Power

When placing larger orders, buyers may have more leverage to negotiate lower prices with suppliers. Manufacturers often offer discounts for high-volume orders to secure bigger contracts.

- Higher volume orders provide leverage for better price negotiations.

- Smaller orders are less likely to receive discounts, leading to higher prices.

3. Production Efficiency

Larger orders typically mean that the factory can streamline the production process and operate more efficiently. This can lead to faster turnaround times and potentially lower labor costs, all of which contribute to lower unit costs.

- Larger orders allow manufacturers to work at full capacity, improving efficiency.

- Smaller orders may not optimize production capacity, leading to higher costs.

| Order Volume Factor | Description | Impact on Pricing |

|---|---|---|

| Economies of Scale | Larger orders spread setup costs across more units | Reduces per-unit price for bulk orders |

| Negotiating Power | Bigger orders allow for better negotiation terms | Higher discounts for larger orders |

| Production Efficiency | Large orders allow for streamlined production | Increases efficiency and reduces labor costs per unit |

Why Should You Consider Long-Term Pricing Strategies When Ordering Custom Parts?

Long-term pricing strategies are crucial when sourcing custom parts to ensure cost stability and predictability. By planning for the long term, businesses can lock in favorable pricing, reduce the impact of price fluctuations, and improve overall supply chain stability.

While short-term cost considerations are important, long-term pricing strategies offer a more strategic approach to sourcing custom parts. Here’s why they are important:

1. Price Stability

By negotiating long-term agreements with suppliers, businesses can lock in more stable prices. This helps avoid the unpredictability of fluctuating prices due to market conditions, material costs, or exchange rate fluctuations.

- Long-term contracts offer predictable pricing, reducing cost volatility.

- Short-term agreements may result in unpredictable price hikes.

2. Better Terms and Discounts

Suppliers are often more willing to offer favorable terms, discounts, or incentives for long-term orders. A commitment to regular business can lead to cost savings and stronger supplier relationships.

- Long-term agreements can come with bulk discounts or better payment terms.

- Smaller, one-time orders may not attract such benefits.

3. Improved Planning and Budgeting

Long-term pricing allows businesses to plan better and manage their budgets more effectively. Knowing the price in advance for a longer period helps companies forecast their expenses and plan accordingly.

- Long-term pricing ensures better budget control and financial forecasting.

- Uncertain pricing in short-term contracts makes it harder to manage expenses.

4. Stronger Supplier Relationships

Commitment to long-term orders fosters stronger, more reliable relationships with suppliers. This leads to better communication, priority in production schedules, and sometimes more favorable treatment in case of supply chain disruptions.

- A long-term partnership often results in a more collaborative relationship with suppliers.

- Reliable partnerships lead to more consistent production timelines and better overall service.

| Long-Term Pricing Strategy | Description | Impact on Pricing |

|---|---|---|

| Price Stability | Lock in prices to avoid market fluctuations | Ensures predictable costs over time |

| Better Terms and Discounts | Negotiating long-term deals may result in discounts | Lower overall pricing and better terms |

| Improved Planning and Budgeting | Long-term contracts allow for easier budgeting and forecasting | Helps businesses manage expenses more effectively |

| Stronger Supplier Relationships | Long-term contracts build trust and collaboration | Results in better service and priority treatment |

Conclusion

The pricing of customized metal parts depends on various factors such as design complexity, order volume, and long-term strategies. By understanding how each of these elements influences costs, businesses can make better decisions, optimize their budgets, and ensure they receive high-quality parts at competitive prices.

Understanding how complexity affects pricing can help businesses make informed decisions and optimize costs. ↩

Exploring tooling costs can reveal how initial investments affect overall pricing, crucial for budgeting. ↩

Learning about production time’s impact on costs can help businesses plan better and avoid unexpected expenses. ↩