Today we share a case where we produced accessories for a world-renowned Off-Road vehicles brand. This client wants to make a batch of stainless steel bands as accessories for their fuel tanks. He provided us with the design drawing of the accessory, and we produced it.

Although we have cooperated with this client for many years, we still develop products strictly according to the process to ensure that the products and services we provide satisfy the client.

Supplier Selection

Based on our mastery of the information and technologies of many auto parts factories, we first screened out several suitable factories as pending options according to the manufacturing conditions of the parts. Then our SQE went to these factories for on-the-spot inspection and factory inspection. We inspected and recorded the product category, most competitive products, production capacity, leading production equipment, raw material, and other information of each factory, and then issued a dolphin report on each factory for the client.

The content of the dolphin report includes information about the factory and our evaluation of the factory in various aspects. Besides, we compare several dolphin reports and provide a copy of our proposal for the client’s reference. Finally, the client chose a factory that was suitable in all aspects based on our suggestions.

Performance Testing

The client’s performance testing requirements exceed the existing test capacity of the factory. The DEWIN team helped the client to contact a professional third-party testing organization, connected with the factory engineer, and finally completed the performance test. The product quality met the client’s requirements. Details are as follows:

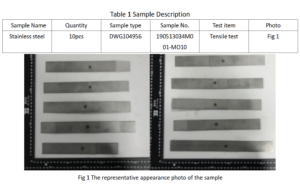

Sample Description

The client submitted a 1pc sample for testing. The sample description is shown in Table. The representative appearance photo of the model before the test was conducted in Fig.1

Testing Method

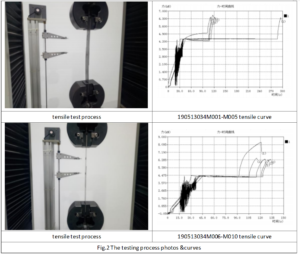

According to < GB/T 228.1-2010 Metallic materials -Tensile testing -Part 1: Method of test at room temperature>&the client’s requirements, Tensile tests were performed. The testing

process photos are shown in Fig. 2

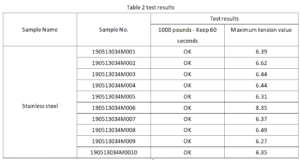

Test Result

Tensile test results are shown in table2. The photo after tested is shown in Fig. 3

Due to our careful work and strict service procedures every time, we have reached good long-term cooperation with this client.