Can you get mid‑production samples when you import custom metal parts from Vietnam?

I’ve faced that moment where you approve the first article, wait weeks, and then discover mid-run defects too late to fix them. Yes — you

I’ve faced that moment where you approve the first article, wait weeks, and then discover mid-run defects too late to fix them. Yes — you

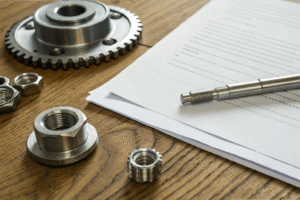

I’ve seen what happens when a part ships and the dimensions don’t match the drawing — downstream customers are upset, production stops, and you bear

I’ve been on orders where a supplier resisted an independent inspection — and you could sense the risk rising immediately. Yes — in fact, it’s

I’ve been down this road many times — waiting for crucial parts, wondering if production is really on schedule, and facing the fallout when it

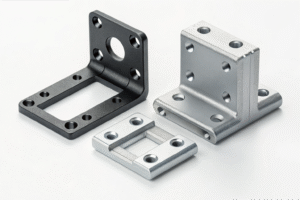

When I first ordered just 30 pieces of a stainless bracket from a Vietnamese factory, the quote shocked me—the per-unit price was 70% higher than

I remember the first time I asked for just 25 pieces of a CNC-machined bracket in Vietnam—the factory pushed back, but once I showed them

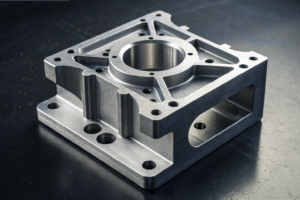

I’ve found that cost isn’t always reduced by pushing harder—it’s often lowered by working smarter, especially when sourcing custom parts from Vietnam. To lower costs

The first time I asked a Vietnamese supplier to hold a quote for 90 days, I got a polite refusal—they said aluminum prices had already

I’ve seen how tempting it is for factories to quietly blend scrap or substitute cheaper metals in castings—it can cut costs fast, but it’s risky

I once had a shipment detained in U.S. customs just because the wooden crate lacked an ISPM 15 stamp. That minor oversight delayed delivery by

When I received a quote from a Vietnamese factory a few years ago, I thought everything was included—until the shipment arrived loosely stretch-wrapped on a

When I reviewed some recent cost breakdowns from our Vietnam partners, I noticed something surprising: even in precision-machined parts, labor wasn’t the top cost driver—it

We will contact you within 24 hrs, please pay attention to the email with the suffix “@dewintech.com”. Your privacy is safe, we won’t use your email for any other purposes. Download NDA