When scaling up production, one of the most critical aspects is ensuring that the samples reflect the final product. But how can you achieve consistency across the board?

Ensuring the consistency of product quality is vital in production management. It starts with effective sample production, which guarantees that large-scale manufacturing meets the set standards.

In the next sections, we'll explore the key elements that contribute to achieving consistency in large-scale production, focusing on product quality, accuracy, and measurement precision.

What is consistency of product quality?

Consistency is the backbone of quality management. Without it, even the most well-designed products could fall short of expectations.

Consistency in product quality refers to ensuring that every unit produced meets the same standards as the prototype or sample, regardless of the production scale.

Consistency in product quality isn't just a buzzword—it's essential to maintaining customer trust and brand integrity. When manufacturing at a large scale, there’s always the risk that small variations between samples and mass production could arise. This can lead to defects, deviations in performance, or even safety concerns. That's why product consistency should be built into every phase of production.

To ensure product consistency, start with thorough testing of the prototype. If you’re working with a supplier, a well-crafted sample that meets your specifications should be treated as the benchmark for all future batches. Any deviation from the sample can lead to inconsistencies that affect the final product's usability and quality. Regular inspection during production1 is also crucial. For example, visual and physical inspections at key stages help ensure the product's dimensions, material properties, and overall finish match the sample.

Key elements of consistency:

| Element | Action | Importance |

|---|---|---|

| Prototype Testing | Test initial samples thoroughly to match design specs. | Ensures that future batches stay on target. |

| Regular Production Checks | Perform visual and physical inspections at different stages. | Detects deviations early to prevent defects. |

| Statistical Process Control2 | Use statistical tools to monitor production. | Helps in identifying and correcting variations. |

| Clear Communication | Maintain communication with suppliers and manufacturers. | Avoids misunderstandings and ensures uniformity. |

Another common method is the use of statistical process control (SPC). This involves monitoring and controlling the production process through the use of statistical methods, ensuring that deviations from the desired quality level are detected early. Regular audits of the manufacturing process—both in terms of machine calibration and worker training—are necessary to make sure consistency is not lost over time.

Finally, consistency also relies on clear communication between you and the factory. If there’s a misunderstanding in design, material choice, or manufacturing processes, the results will be noticeable in the final product.

To summarize, ensuring consistency requires a holistic approach, starting from the very first sample and continuing throughout the entire production process.

What ensures accuracy of the final product?

The accuracy of the final product depends on a precise alignment of every factor from design to production. But what exactly makes this accuracy possible?

Accuracy in production3 involves exact adherence to design specifications, material requirements, and production parameters. Several checks and measures ensure the final product aligns with the sample.

Accuracy in product manufacturing is often about precision at every stage. It's not just about sticking to the sample; it's about sticking to a blueprint that defines each detail. If you’re dealing with customized parts, accuracy ensures that every item fits perfectly, performs as expected, and meets safety standards.

One of the most essential tools in ensuring accuracy is a well-structured design review process4. This step involves scrutinizing the initial designs and comparing them to past successful productions to prevent mistakes before they even occur. This process might also involve simulating how the final product will behave under different conditions.

Accuracy checklist:

| Factor | Action | Importance |

|---|---|---|

| Design Review | Conduct thorough reviews to ensure alignment with prior successful designs. | Prevents design-related errors early. |

| Machine Calibration | Regularly calibrate precision equipment. | Ensures tools are functioning as expected. |

| Worker Expertise | Train staff to handle precision tools and techniques. | Enhances the accuracy of manual adjustments. |

| Post-production Testing | Conduct further tests to verify final product meets specifications. | Ensures accuracy in final products. |

In large-scale production, having accurate measurements and equipment calibration is critical. Automated systems that measure components with micrometer-level precision ensure that even the smallest variations are detected. Machines like CNC (Computer Numerical Control) routers5, for instance, offer high-precision machining that guarantees accuracy in custom parts. These systems can often identify minute deviations from the design specification that could otherwise go unnoticed.

Besides machine calibration, worker skill plays a significant role in accuracy. Skilled operators can manually inspect and adjust small imperfections that automated systems might miss. A team with a deep understanding of the process will know how to maintain product accuracy without relying solely on machines.

Incorporating regular quality control checks, from raw material inspection to post-production testing, ensures that any discrepancies are caught before the product leaves the factory. These inspections ensure that the final products are within the acceptable tolerance levels.

The goal is to create a process that minimizes the risk of error and ensures that the final product aligns perfectly with your expectations.

How do you ensure accurate measurements?

When it comes to ensuring that the measurements are spot on, it's not just about having the right tools. It’s about knowing how to use them effectively.

Accurate measurements are essential for ensuring that the final product matches specifications. Calibrated tools, regular checks, and accurate data management practices play an integral role in this process.

Accurate measurements are a cornerstone of quality control in manufacturing, especially when producing customized parts. Even the smallest error in measurement can result in a defective product or misfit, leading to waste, delays, or customer dissatisfaction. So, ensuring accuracy begins with using the right measuring instruments and maintaining them properly.

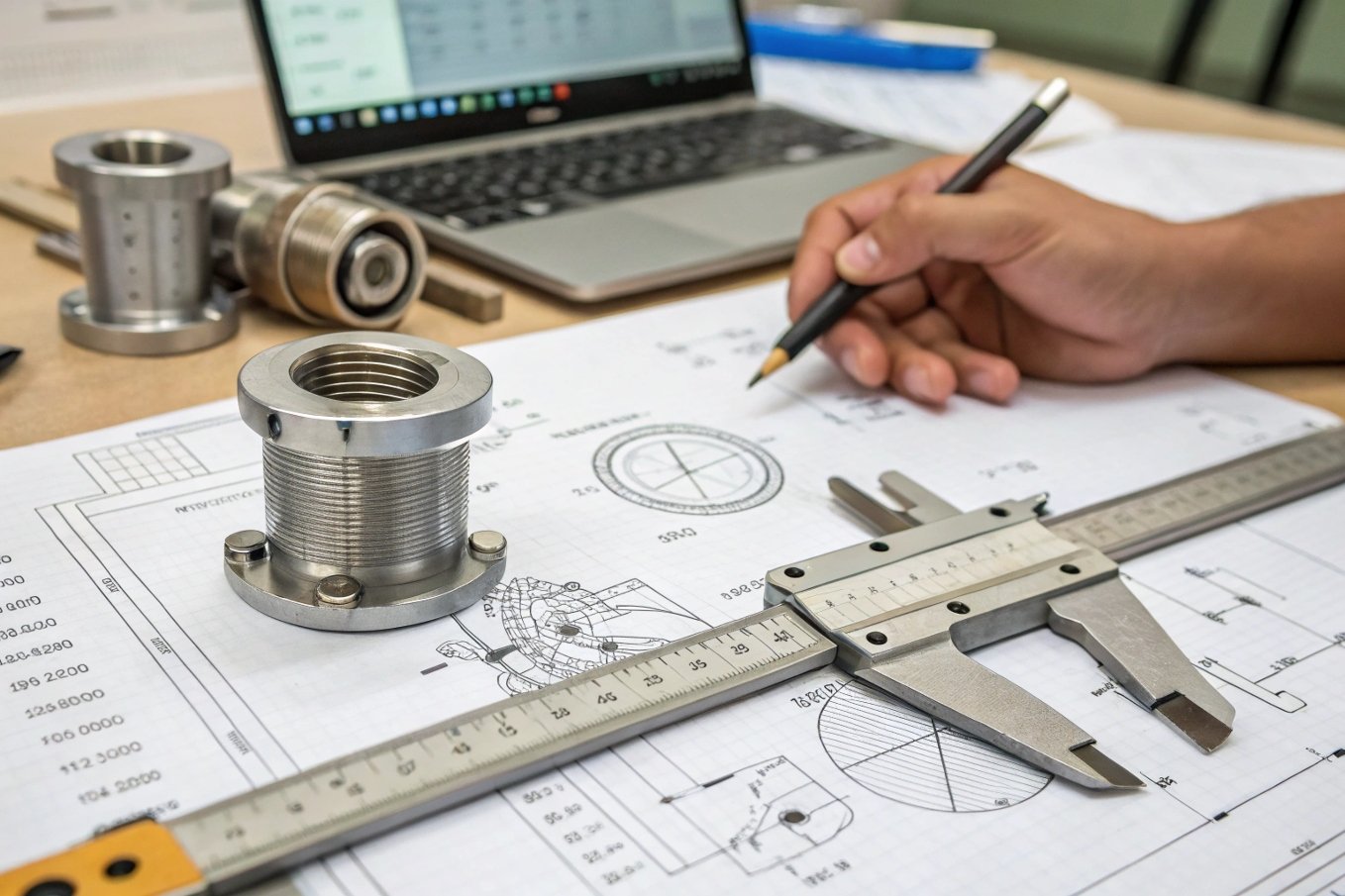

First, let's talk about the tools. Precision measuring tools, such as micrometers, calipers, and coordinate measuring machines (CMM), are necessary for verifying the dimensions of the parts at each stage of production. A micrometer, for example, can measure dimensions with a resolution down to 0.0001 inch. These tools must be calibrated regularly to ensure their accuracy, as even the slightest calibration drift can cause discrepancies in measurements.

Measurement tools:

| Tool | Accuracy Level | Use Case |

|---|---|---|

| Micrometer | 0.0001 inch | Measures small dimensions with high precision. |

| Caliper | 0.01 mm | Measures larger parts or distances with good accuracy. |

| Coordinate Measuring Machine | 0.0001 inch | Measures complex shapes and dimensions in 3D. |

Then, there’s the importance of measurement techniques. Sometimes, even with accurate tools, poor handling or improper techniques can lead to errors. For instance, a part might be measured in a way that doesn’t reflect its true dimensions or doesn’t account for environmental factors like temperature, which can affect material size.

Furthermore, integrating accurate measurements into a data management system ensures that you’re constantly monitoring the measurements of each batch and can quickly identify any issues. Modern measurement systems often come with built-in software that stores measurement data, allowing you to track trends and identify potential issues early. With this information, you can make adjustments to the production process before problems arise.

The goal is to create an environment where measurements are not only accurate but also repeatable and traceable. This way, you can ensure that no matter how many units are produced, the measurements will always align with your specifications.

Conclusion

Achieving consistency in large-scale supply requires tight control over the sample production, accurate measurements, and robust quality management systems.

-

Learning about the role of regular inspections can help you implement better quality assurance practices in your production process. ↩

-

Exploring SPC can provide insights into effective quality control methods that minimize defects and ensure product reliability. ↩

-

Explore this link to discover essential practices that enhance accuracy in production processes, ensuring high-quality outcomes. ↩

-

Learn how a structured design review process can prevent costly mistakes and enhance product accuracy in manufacturing. ↩

-

Find out how CNC routers can improve precision and efficiency in manufacturing, ensuring high-quality custom parts. ↩