When I reviewed some recent cost breakdowns from our Vietnam partners, I noticed something surprising: even in precision-machined parts, labor wasn’t the top cost driver—it was raw materials 1.

Typically, labor accounts for 17–22% of the total manufacturing cost for custom metal parts sourced from Vietnam. That percentage can go up or down based on process complexity, automation, and volume.

In this article, I’ll explain what determines labor’s share in your import costs and how you can influence it.

What labor cost percentage is typical?

This range comes from both industry reports and our sourcing experience: simple parts trend toward 15%, while highly machined or assembled parts creep closer to 25%.

In most of our projects involving Vietnamese metal suppliers, labor tends to make up 15–25% of the total landed cost—less than you might expect.

This observation aligns with industry cost reports for Vietnam manufacturing 2, which show that labor share varies depending on part complexity and automation levels.

Labor Share Benchmarks by Process Type

| Process Type | Typical Labor Share (%) | Notes |

|---|---|---|

| Basic stamping/sheet metal | 10% – 15% | High automation, low manual work |

| CNC machined (medium complexity) | 15% – 22% | Setup + skilled operator labor adds cost |

| Precision machining + finishing | 20% – 30% | High skill, longer cycle times |

| Welding + assembly + QC | 25% – 35% | Includes indirect labor (QA, inspection, assembly line) |

Labor costs in Vietnam are still low compared to China or the U.S., but they are rising every year, which slowly shifts this percentage upward over time.

However, Vietnam’s annual wage growth trend 3 shows that this gap is narrowing.

How do complexity & precision affect labor share?

Complex shapes, tight tolerances, and manual operations like deburring or assembly increase operator time and reduce opportunities for automation—raising labor’s share of total cost.

I’ve found that labor becomes a bigger piece of the cost puzzle when parts get more detailed.

For instance, tight tolerances and manual finishing processes 4 often increase operator time and limit automation opportunities—raising total labor share.

Let’s break this down a bit more:

Complexity Factors That Drive Up Labor Share

- Tight Tolerances: Tighter tolerances demand slower machining, more tool changes, and higher-skilled workers.

- Manual Finishing: Hand polishing, cleaning, or post-machining often can’t be automated.

- Assembly Work: Bolting, welding, or joining parts increases indirect labor.

- Inspection & QC: Complex parts may require 100% dimensional inspection or functional testing.

- Rework Risk: Higher part complexity increases the chance of defects, which adds to labor cost.

Labor Share Ranges Based on Part Complexity

| Part Complexity Level | Estimated Labor Share | Example Features |

|---|---|---|

| Low (simple stamping) | 10% – 15% | No finishing, no tight tolerances, no assembly |

| Medium (machined part) | 15% – 25% | Tolerances ±0.1 mm, one or two finishes |

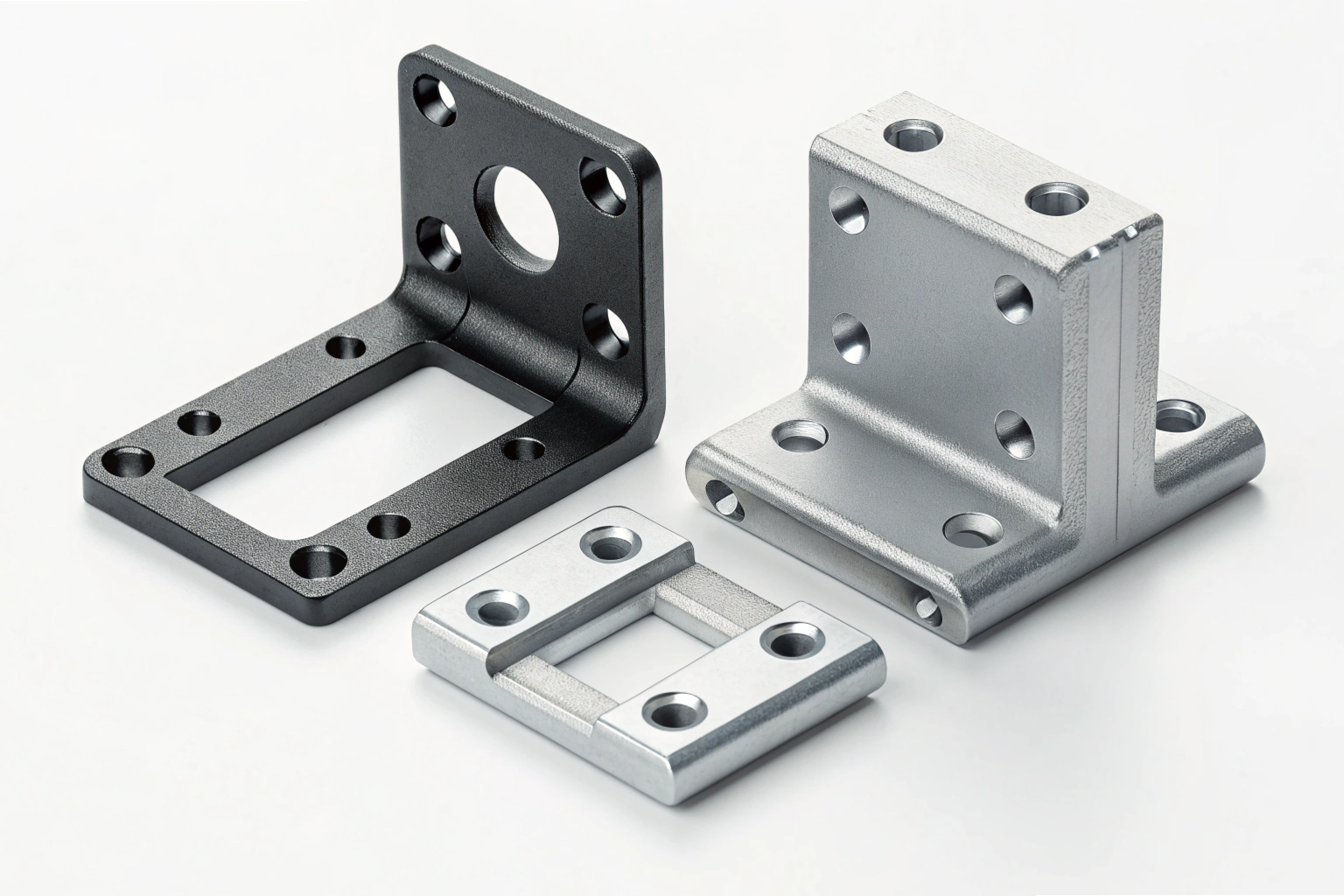

| High (precision + finish) | 25% – 35% | ±0.01 mm, polish, weld, full QC, assembly steps |

If your design calls for precision features like threads or ±0.01 mm tolerances 5, you can expect labor costs to rise—even in low-wage regions.

Does volume reduce labor percentage?

Larger production runs spread out setup time and increase operator efficiency, reducing labor’s share of each unit.

Yes, and it’s one of the strongest cost levers.

Larger production batches 6 help distribute setup and changeover time over more parts, lowering labor’s per-unit share dramatically.

Labor Cost Impact Based on Batch Size

| Batch Size | Typical Labor Share | Notes |

|---|---|---|

| 1–50 units | 25% – 35% | Setup, testing, first-article approval dominate |

| 100–1,000 units | 18% – 25% | Setup amortized, operator efficiency improves |

| 5,000+ units | 10% – 18% | High efficiency, process refinement, faster cycles |

Even in Vietnam, this economy of scale effect 7 is quite visible—batching production runs remains one of the best ways to cut labor share.

How do automation & tooling reduce labor cost?

Automation shifts cost from labor to capital and tooling—but that’s often a good tradeoff over time.

When factories adopt automation technologies such as robotic arms and pallet changers 8, they shift cost from labor to equipment and tooling. This often yields better consistency and long-term savings.

Tooling matters too—custom fixtures and indexed tool changers 9 minimize handling time and improve throughput, reducing operator involvement.

If your design supports repeatable setups, it’s worth discussing automation strategy with your supplier 10 to understand how it affects the overall labor-to-capital balance.

Conclusion

Labor typically makes up 15–25% of the landed cost when importing custom metal parts from Vietnam, with complexity, volume, and automation being the key influencers. Understanding this helps you make smarter sourcing and negotiation decisions.

Footnotes

1. Explanation of how material costs dominate over labor in Vietnam. ↩︎

2. Industry data confirming typical labor shares in Vietnam manufacturing. ↩︎

3. Report on Vietnam’s manufacturing wage growth trends. ↩︎

4. Why tight tolerances and manual finishing increase labor input. ↩︎

5. Impact of precision design features on total labor cost. ↩︎

6. Benefits of large-batch production in reducing unit labor share. ↩︎

7. Overview of scale efficiency effects in Vietnamese manufacturing. ↩︎

8. How factory automation reduces reliance on human labor. ↩︎

9. Role of tooling and fixturing in lowering labor intensity. ↩︎

10. Guide to discussing automation strategy with suppliers. ↩︎