Running our own operations in Vietnam has taught us that sourcing technical components is fundamentally different sourcing technical components 1 from buying off-the-shelf goods. When we develop complex automotive air ducts or industrial reservoirs, we quickly realize that the local supply chain is evolving but requires hands-on navigation to distinguish capable engineering firms from simple packaging factories.

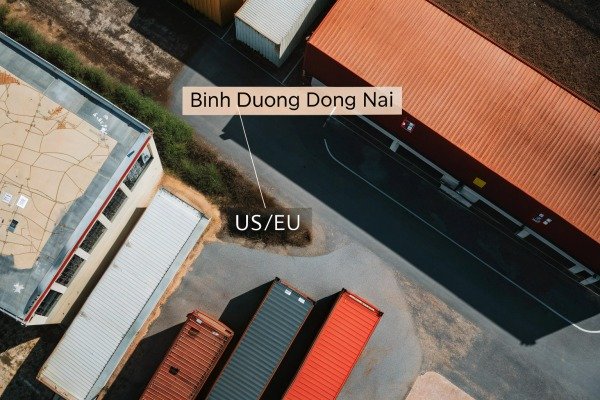

To find reputable suppliers, start by targeting industrial clusters in Binh Duong and Dong Nai using platforms like Vietnam Export. Always filter for manufacturers with verified export history to the US or EU, and validate their capabilities by inspecting their specific machinery for industrial parts.

Once you have identified a list of potential candidates, the real work begins in verifying their ability to execute your specific design.

Where can I look for reputable plastic blow molding suppliers in Vietnam?

During our years of sourcing custom parts for US clients sourcing custom parts 2, we have found that generic online searches often lead to trading companies rather than actual factory owners. We prefer digging deeper into specific industrial databases where the serious players in the polymer industry list their true capabilities.

Focus your search on industrial hubs like Binh Duong and Ho Chi Minh City, using local trade shows such as VietnamPlas for direct contact. Supplement this with digital directories that verify manufacturer status, avoiding general trading companies to ensure direct access to production capabilities.

The landscape of Vietnamese manufacturing is geographically concentrated Vietnamese manufacturing 3, and knowing where to look is half the battle. Unlike China, where manufacturing is spread across vast provinces, Vietnam’s plastic blow molding industry is heavily clustered in the South.

The Southern Industrial Clusters

If you are looking for high-quality technical parts—like the automotive air ducts shown in your product concepts—your primary target should be the industrial zones surrounding Ho Chi Minh City. Specifically, Binh Duong and Dong Nai provinces are the heart of the country’s plastic injection and blow molding sector.

- VSIP (Vietnam Singapore Industrial Park): This is where many export-oriented factories are located. Suppliers here are accustomed to Western standards and English communication.

- Dong Nai Industrial Zones: Often host larger facilities that support the automotive and appliance supply chains.

Online Directories vs. Trade Shows

While Alibaba is a common starting point, it is often saturated with traders. For a more direct line to manufacturers, we recommend using local specialized directories and cross-referencing them with trade show exhibitor lists.

Comparison of Sourcing Channels in Vietnam

| Sourcing Channel | Pros | Cons | Best For |

|---|---|---|---|

| VietnamPlas (Trade Show) | Direct access to factory owners; physical sample inspection. | Requires travel; occurs only once a year. | Verifying machine types and physical quality. |

| Yellow Pages Vietnam | Extensive list of local firms; includes smaller workshops. | Many listings are outdated; language barriers are common. | Finding low-cost, domestic-focused suppliers. |

| Specialized Sourcing Agencies | Local teams verify legitimacy; handles language/logistics. | Adds a service fee to the unit cost. | Complex custom projects requiring strict QC. |

| Global B2B Platforms | Easy to search; Trade Assurance options. | High percentage of trading companies; higher pricing. | Quick RFQs for standard commodity products. |

The "Bottle" vs. "Industrial" Trap

A critical insight we apply when filtering suppliers is distinguishing between packaging blow molders and technical blow molders. Vietnam is a global leader in blowing PET bottles for beverages PET bottles 4. However, a factory that makes water bottles usually lacks the accumulation blow molding machinery required for irregular blow molding machinery 5 industrial parts. When you search, look specifically for keywords like "technical blow molding," "automotive plastic parts," or "industrial hollow parts" to avoid wasting time with packaging vendors.

How do I verify if a Vietnamese factory can handle my custom project requirements?

We often encounter suppliers who claim they can manufacture anything, only to discover later that they intend to outsource the entire project. When we vet a partner for a complex project, we look past the sales pitch and examine the hardware on the factory floor.

Examine their specific machinery list to confirm they have accumulator head blow molding machines suitable for complex industrial parts rather than just bottle blowing equipment. Request a full equipment list and past project portfolios that demonstrate experience with similar wall thickness and geometric complexities.

Verifying technical capability is the most critical step in the sourcing process, especially for non-standard parts like automotive ducts or medical containers. In Vietnam, the technology gap between top-tier exporters and local workshops can be massive.

Machinery Mismatch: The Accumulator Head Issue

For the matte black components with mounting tabs and irregular shapes described in your requirements, standard continuous extrusion blow molding (used for milk jugs) is often insufficient. You need to confirm the factory possesses Accumulator Head Blow Molding machines.

These machines allow the parison (the molten plastic tube) to be pushed molten plastic tube 6 out quickly, which is essential for large or thick-walled parts to prevent the plastic from cooling unevenly before the mold closes. If a supplier delays sending you their equipment list, it is a major red flag.

Analyzing the "Reference Sample"

Do not just ask for "samples." Ask for samples that demonstrate specific challenges:

- Uniform Wall Thickness: Cut a sample part in half. In blow molding, corners are notoriously thin. A capable supplier will have parison programming capabilities to control thickness at 100 points or more.

- Surface Finish: The matte texture on your parts requires acid-etched or sandblasted molds. Ask if they have experience maintaining textured molds, as these can wear down quickly if low-quality steel is used.

- Flash Trimming: Look at the seams. Is the excess plastic (flash) trimmed by a robot or by hand? In Vietnam, manual trimming is common due to low labor costs, but it leads to inconsistency. For high-volume automotive parts, we prioritize factories with automated de-flashing systems.

Material Sourcing Verification

Vietnam relies heavily on imported virgin resin (PP, HDPE, ABS) imported virgin resin 7 from the Middle East, Korea, and China. A factory’s ability to handle your project depends on their supply chain.

- Ask: "Do you buy resin directly from the producer or through local distributors?"

- Why: Buying from local distributors increases price volatility. Direct importers are more stable.

- Ask: "Do you use regrind (recycled material)?"

- Why: For structural parts, regrind percentage must be strictly controlled (usually under 20%). Ensure they have the equipment to mix this precisely, not just throw scraps back into the hopper manually.

What steps should I take to audit a potential supplier in Vietnam?

Our engineers frequently visit facilities in Binh Duong Binh Duong 8, and we have learned that a shiny conference room does not guarantee a clean production line. We always insist on walking the floor to see how raw materials are handled and how molds are maintained.

Conduct an on-site audit to verify the existence of the facility and assess their quality management systems against ISO 9001 quality management systems 9 standards. Evaluate their raw material storage conditions and mold maintenance area to ensure they can sustain long-term production without unexpected downtime or quality degradation.

An audit in Vietnam serves two purposes: verifying the business exists (avoiding scams) and verifying the process capability. You or your representative must be physically present.

The "Three-Zone" Audit Approach

When we walk through a factory, we divide our attention into three critical zones. If any of these fail, the supplier is rejected.

Zone 1: The Material Preparation Area

This is often the most neglected area. Blow molding involves hygroscopic materials that absorb moisture.

- Check: Are there industrial dehumidifying dryers?

- Red Flag: Open bags of resin sitting on the floor in high humidity. This leads to bubbles and weak spots in the final part.

- The Mix: Verify how color masterbatch is added. Is it an automated doser (good) or a worker with a scoop (bad)?

Zone 2: The Mold Maintenance Shop

Molds for blow molding are subjected to immense pressure and heat cycles.

- Check: Does the factory have an in-house CNC shop for mold repair?

- Why it matters: If a cooling line gets blocked or a pinch-off edge gets damaged, an in-house team can fix it in hours. If they have to ship the mold to an external vendor, your production could be down for weeks.

Critical Audit Checklist for Vietnam Suppliers

| Audit Focus | What to Look For | Significance |

|---|---|---|

| Machine Maintenance | Logs attached to machines showing oil changes/repairs. | Prevents sudden breakdowns mid-production. |

| Worker Discipline | Are operators wearing PPE? Is the floor clean of oil/granules? | Indicates overall management culture and safety. |

| Quality Lab | Calibrated calipers, leak testers, and drop-test setups. | ensures they can test according to ASTM/ISO standards. |

| Scrap Management | Clearly labeled bins for different resin types. | Prevents contamination (e.g., mixing PP with HDPE). |

The "Yes" Culture

In Vietnamese business culture, it is rude to say "no" directly. A supplier might agree to a tolerance of +/- 0.5mm even if their machine can only hold +/- 1.0mm. During the audit, ask open-ended questions like "How do you achieve this tolerance?" rather than "Can you achieve this tolerance?" If they cannot explain the "how," the "yes" is invalid.

How can I ensure my chosen supplier maintains strict quality control standards?

We know that getting a “Golden Sample” is easy, but getting 10,000 perfect units is the real challenge. We enforce strict protocols from day one, ensuring that the factory understands that our quality expectations are non-negotiable and legally binding.

Implement a rigorous quality agreement that defines acceptable defect rates and specific testing protocols like leak testing or drop tests. Require pre-shipment inspections and material certifications for every batch to prevent unauthorized resin swaps and ensure consistent wall thickness distribution in production.

Consistency is the primary pain point for buyers sourcing from Vietnam. Without a robust QC framework, quality tends to "drift" over time as workers get comfortable or machines wear down.

Defining the "Quality Criteria Sheet"

Before a single dollar is transferred, you must co-develop a Quality Criteria Sheet (QCS). Do not rely on "industry standards."

- Visual Defects: Create a photo catalog of acceptable vs. unacceptable defects. For your matte black parts, are flow lines matte black parts 10 acceptable? Is a 0.5mm scratch on the back side okay? Define this visually.

- Functional Testing: For blow molded parts, leak testing is non-negotiable if the part holds fluid or air.

- Our Advice: Mandate 100% inline leak testing for critical automotive ducts. For non-critical parts, a random sampling plan (AQL 2.5) is sufficient.

Controlling the Process parameters

Quality in blow molding is dictated by heat, pressure, and time.

- The "Recipe" Card: Require the factory to document the machine settings (melt temperature, blow pressure, cycle time) used to create the approved sample.

- The Rule: Any change to these settings requires your written approval. This prevents the night shift from speeding up the cycle time (which thins the part) just to finish the shift early.

Third-Party Inspections

Even with a trusted relationship, we always recommend "trust but verify."

- Pre-Shipment Inspection (PSI): For the first three orders, hire a third-party inspector to check the goods before they leave the factory.

- Raw Material Certification: Demand a Certificate of Analysis (COA) for the resin batch used in production. This ensures they didn't swap your high-grade virgin HDPE for a cheaper, lower-grade alternative to save costs.

Table: Common Blow Molding Defects and Prevention

| Defect Type | Likely Cause | Prevention Strategy |

|---|---|---|

| Thin Corners | Poor parison programming or insufficient blow pressure. | Use Accumulator Head machines; check wall thickness with ultrasonic gauges. |

| Rocker/Warpage | Uneven cooling in the mold. | Verify cooling channel design; increase cooling cycle time. |

| Surface Pitting | Trapped air or moisture in resin. | Verify resin drying logs; check mold venting maintenance. |

| Flash on Parting Line | Clamping force too low or mold misalignment. | Regular mold maintenance checks; automated trimming. |

Conclusion

Finding the right blow molding partner in Vietnam is a strategic move that can significantly lower your landed costs while diversifying your supply chain risk. By focusing on the industrial clusters of Binh Duong, distinguishing between packaging and industrial specialists, and enforcing strict on-site audits, you can secure high-quality custom parts. Success lies not just in finding a factory, but in actively managing the technical relationship.

Footnotes

1. WHO fact sheet regarding the regulation and sourcing of medical devices and technical components. ↩︎

2. Wikipedia entry defining the business practice of outsourcing and global sourcing strategies. ↩︎

3. Overview of the manufacturing sector and industrial development within the country of Vietnam. ↩︎

4. Technical information about Polyethylene terephthalate, the material used for common plastic bottles. ↩︎

5. Detailed explanation of the blow molding manufacturing process used to create hollow plastic parts. ↩︎

6. Definition of a parison, the precursor tube used in the blow molding manufacturing process. ↩︎

7. EPA resources regarding the classification and environmental impact of various plastic resin types. ↩︎

8. Geographic context for the industrial hub. ↩︎

9. Official homepage for international standards governing quality management and operational consistency. ↩︎

10. Wikipedia article explaining quality assurance protocols and defect management in manufacturing. ↩︎