Choosing the right factory for custom manufacturing1 is crucial for the success of your project. The factory you select will play a significant role in the quality, cost, and delivery time of your custom parts. Selecting the wrong one can lead to delays, increased costs, and unsatisfactory products. It’s important to carefully evaluate potential factories to ensure they align with your project’s needs.

The best factory for custom manufacturing is one that can meet your quality standards, production timeline, and cost targets while maintaining clear communication throughout the process.

In this article, we’ll explore the key factors to consider when evaluating potential factories for custom parts production and why it’s important to visit the factory before finalizing any deals.

What Criteria Should You Use to Evaluate a Factory for Custom Parts Production?

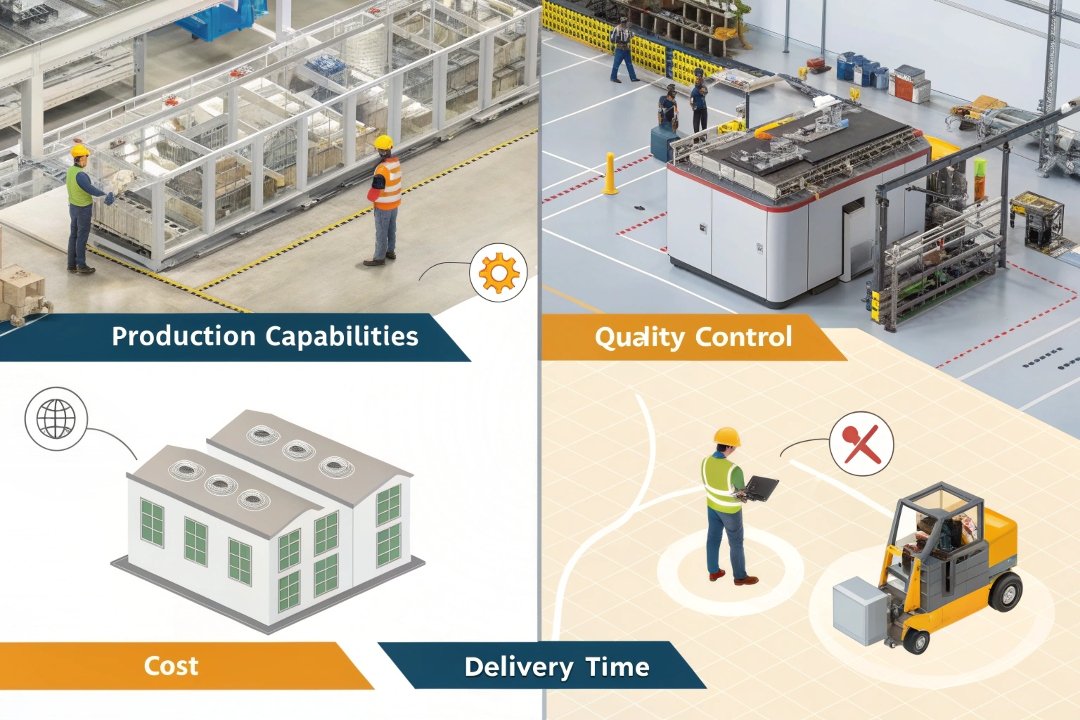

To evaluate a factory for custom parts production, several criteria should be considered, including their manufacturing capabilities2, experience, reputation, and quality control systems3. These factors ensure the factory can meet your specifications and produce parts on time.

When choosing a factory for custom manufacturing, it’s essential to evaluate multiple aspects to ensure they meet your needs. Here are the key criteria to consider:

1. Manufacturing Capabilities

The factory’s ability to handle the complexity of your custom parts is crucial. Assess whether they have the right equipment, technology, and skilled labor to produce the specific parts you need. This includes evaluating their machinery for precision, speed, and scalability.

- Does the factory have the necessary equipment for your part’s production process?

- Can they handle the required volume?

- Are they capable of producing parts to the exact tolerances required?

2. Experience and Specialization

Choose a factory with experience in producing the type of custom parts you need. Specialized manufacturers who understand the materials, production techniques, and quality standards associated with your parts are more likely to deliver high-quality products.

- How long has the factory been in business?

- Do they specialize in the specific industry or type of part you require?

- Have they handled similar projects successfully in the past?

3. Quality Control Systems

A factory with strong quality control systems is critical to ensuring that the custom parts meet your specifications and standards. Ask about their quality control processes, including inspection methods, testing protocols, and certification standards (e.g., ISO).

- Do they have quality control measures in place at each stage of production?

- Are they able to provide certifications for the parts?

- How do they handle defects or rework?

4. Production Lead Times

Timely delivery is essential in custom manufacturing, especially when meeting tight deadlines. Evaluate the factory’s ability to meet your production schedule and any potential delays that could affect your project timeline.

- What is their typical lead time for custom parts?

- Can they meet your required delivery dates consistently?

5. Communication and Support

Effective communication with the factory is essential throughout the production process. Evaluate how responsive the factory is to your inquiries and how well they provide updates and support during production.

- Are they quick to respond to your emails or calls?

- Do they offer regular progress updates?

- Do they provide dedicated support for your project?

| Evaluation Criteria | Key Considerations | Benefits |

|---|---|---|

| Manufacturing Capabilities | Are they equipped to handle your part’s production requirements? | Ensures the factory can meet your specific production needs |

| Experience and Specialization | Do they have experience in your industry or with similar parts? | Reduces the risk of mistakes and ensures high-quality results |

| Quality Control Systems | Do they have strong quality assurance protocols? | Guarantees parts meet required specifications and standards |

| Production Lead Times | Can they meet your delivery deadlines? | Ensures timely delivery of your custom parts |

| Communication and Support | Are they responsive and provide regular updates? | Keeps you informed and ensures smoother project management |

How Can You Ensure the Factory Meets Your Custom Parts Requirements?

To ensure a factory meets your custom parts requirements, establish clear specifications, conduct factory audits, and set expectations for quality control and timelines from the outset.

Once you’ve identified a potential factory, it’s essential to take steps to ensure they can meet your exact requirements for custom parts. Here are some effective strategies to ensure alignment:

1. Provide Detailed Specifications

The first step in ensuring a factory can meet your requirements is to provide detailed, clear specifications for your custom parts. This includes:

- Materials and finishes

- Design and dimensions

- Tolerance levels

- Quality standards and certifications

The more specific you are with your requirements, the easier it will be for the factory to meet them. Be sure to outline your expectations regarding quality control and any other specific requests (e.g., packaging, labeling, etc.).

2. Conduct a Factory Audit

A factory audit is a thorough evaluation of the factory’s capabilities, quality control processes, and overall operations. Conducting an audit before committing to a partnership helps verify that the factory can meet your requirements.

- Evaluate their facilities and equipment

- Review their quality control processes

- Check references and previous projects

An audit helps uncover any potential issues before production starts and ensures the factory meets your standards.

3. Request Prototypes or Samples

Before full-scale production begins, ask the factory to produce prototypes or samples of your custom parts. This allows you to assess the quality, precision, and fit of the parts before committing to a larger order.

- Are the samples made to the required specifications?

- Do the parts meet your quality standards?

- Are there any issues that need to be addressed before full production begins?

4. Set Clear Expectations for Communication and Updates

Communication is essential to ensuring that the factory meets your custom parts requirements. Set expectations for regular updates on progress, quality checks, and any issues that arise during production. Establishing these protocols from the beginning helps prevent misunderstandings.

| Assurance Strategy | Key Considerations | Benefits |

|---|---|---|

| Provide Detailed Specifications | Are your part requirements clear and comprehensive? | Ensures the factory understands your needs and can produce accordingly |

| Conduct a Factory Audit | Does the factory meet your quality standards and operational expectations? | Verifies that the factory can meet your requirements and avoid potential issues |

| Request Prototypes or Samples | Do the prototypes meet your design and quality requirements? | Allows you to confirm quality before large-scale production begins |

| Set Clear Communication Expectations | Have you agreed on regular updates and progress reports? | Prevents misunderstandings and ensures smooth production management |

Why Is It Important to Visit the Factory Before Finalizing the Deal?

Visiting the factory before finalizing the deal is critical because it allows you to assess the factory’s capabilities, quality control measures, and overall operations in person, reducing the risk of surprises during production.

Visiting the factory in person is an essential step that cannot be overlooked. While virtual meetings and audits can provide some insights, a physical visit allows for a deeper understanding of the factory’s operations. Here’s why it’s important to visit:

1. Evaluate Production Conditions Firsthand

A factory visit provides the opportunity to inspect the production conditions in person. You can observe the cleanliness, organization, and overall efficiency of the facility, which are important indicators of how well they will handle your custom parts production.

- Is the factory organized and well-maintained?

- Are they using up-to-date machinery and technology?

- Are safety standards being followed?

2. Verify Quality Control Systems

Although the factory may provide documentation or reports on their quality control processes, seeing it in action is invaluable. A visit allows you to observe how the factory handles quality control, inspections, and testing during production.

- How do they conduct quality checks at each stage?

- Are quality control processes rigorous and thorough?

3. Build Stronger Relationships

A visit to the factory also provides the opportunity to meet the team, build relationships, and establish trust with key contacts. Having face-to-face interactions can strengthen communication and improve collaboration between your team and the factory’s staff.

- Can you communicate effectively with the team?

- Do you feel confident in their ability to meet your needs?

4. Identify Potential Issues Early

By visiting the factory, you can identify any potential issues early, such as inefficiencies, gaps in production processes, or areas where quality could be compromised. This gives you the chance to address concerns before they become larger problems.

| Visit Benefits | Key Considerations | Benefits |

|---|---|---|

| Evaluate Production Conditions | Are the facilities clean, organized, and well-equipped? | Provides insight into the factory’s operations and capabilities |

| Verify Quality Control Systems | Are quality checks performed consistently and thoroughly? | Ensures that quality control is being maintained throughout production |

| Build Stronger Relationships | Have you established trust and clear communication? | Strengthens collaboration and fosters long-term partnerships |

| Identify Potential Issues Early | Are there any red flags that could impact production? | Allows for early intervention to address any problems before they escalate |

Conclusion

Choosing the right factory for custom manufacturing is a critical step in ensuring the success of your project. By evaluating a factory’s manufacturing capabilities, experience, quality control systems, and communication practices, you can select the best fit for your needs.

Explore this link to understand the best practices that can enhance your custom manufacturing process and ensure quality outcomes. ↩

This resource will guide you on how to effectively evaluate a factory’s manufacturing capabilities to meet your project needs. ↩

Learn about effective quality control systems that can help ensure the quality of your custom parts during production. ↩