We know the frustration of sourcing overseas—receiving samples that look perfect but fail in mass production. Our team has seen this disrupt supply chains too often, especially when strict automotive standards are involved.

To determine if Vietnamese blow molding parts meet US Tier 1 standards, you must verify IATF 16949 certification and validate process capability metrics like Cpk > 1.33. Crucially, audit their ability to execute PPAP requirements and maintain consistent PPM levels below 500 through automated inline leak testing and strict resin controls.

Validating a supplier requires a systematic approach that goes beyond basic trust.

What specific certifications should I look for to ensure compliance with US Tier 1 requirements?

When we evaluate new partners in Vietnam, we often see impressive facilities lacking documentation. Without the right paperwork, consistent quality is just a gamble that puts your production line at risk.

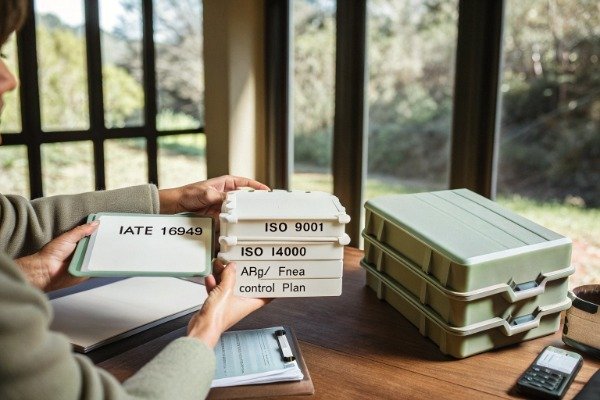

You should primarily look for IATF 16949 certification, which is the baseline for automotive-grade consistency and defect prevention. Additionally, verify ISO 9001 for general management and ISO 14001 for environmental compliance, ensuring the supplier can handle rigorous documentation like APQP, FMEA, and control plans required by US Tier 1 buyers.

The Non-Negotiable Standard: IATF 16949

In the world of US Tier 1 supply chains, ISO 9001 1 is merely the entry ticket. It proves a company has a management system, but it does not guarantee the defect prevention mechanisms required for automotive parts. We have found that for blow molding specifically, IATF 16949 is the critical differentiator. This standard mandates risk-based thinking and specific defect prevention strategies that generic standards overlook.

Currently, the landscape in Vietnam is maturing. Industry reports indicate that only about 30-40% of Vietnamese automotive suppliers hold full IATF 16949 2 certification, compared to roughly 60% in Thailand. This means you must be selective. A supplier without this certification may struggle with the complex Customer-Specific Requirements (CSRs) from OEMs like GM or Ford. For example, GM emphasizes specific warranty data analysis, while Ford has unique PPAP formatting. A factory only familiar with ISO 9001 will likely fail to meet these administrative burdens, leading to delays.

Beyond the Certificate: Verifying Authenticity

We have encountered instances of "certification washing," where a supplier presents a valid ISO 9001 certificate but fails to adhere to the stricter IATF protocols in practice. To avoid this, you must request proof of third-party certification from an accredited body. Do not just accept a PDF; verify it with the issuing agency.

Furthermore, look for evidence of environmental compliance. With rising ESG pressures 3, US Tier 1 companies like Flex are prioritizing supply chain transparency. ISO 14001 certification is becoming increasingly important for waste reduction in blow molding processes.

Documentation as a Proxy for Quality

The certification is not just a wall plaque; it represents the ability to generate critical data. You need to ensure the supplier can produce the following documents, which are standard for Tier 1 compliance:

Table 1: Essential Documentation for Tier 1 Compliance

| Document Type | Purpose in Blow Molding | Why Tier 1 Needs It |

|---|---|---|

| APQP (Advanced Product Quality Planning) | Defines the roadmap for new product launches. | Ensures the supplier plans for quality before cutting steel for molds. |

| PPAP (Production Part Approval Process) | Validates that the production process can consistently produce parts to spec. | Prevents "golden samples" that cannot be replicated in mass production. |

| FMEA (Failure Mode and Effects Analysis) | Identifies potential failure points (e.g., thin walls at corners). | Proactive risk management is cheaper than recalls. |

| Control Plan | detailed instructions for checking quality at every step. | Standardizes inspection so every operator checks the same way. |

How do I effectively audit a Vietnamese supplier's quality control process for blow molded parts?

We have walked through countless factory floors where QC was just a final visual check. Real quality control must happen during production, not just at the end, to prevent costly rework.

Effectively auditing a Vietnamese supplier requires inspecting their entire Quality Management System, not just the final product. You must verify they use real-time process controls, such as automated parison programming and dehumidifying dryers, and demand evidence of "Golden Sample" retention to define acceptable cosmetic limits before mass production begins.

Moving From Product Audit to Process Audit

When we visit a factory, we stop looking at the finished pile of goods and start looking at the machines. For blow molding, the quality is determined inside the mold. You must audit the supplier’s Quality Management System (QMS) to ensure they follow documented process controls. If they rely solely on final inspection to catch defects, they are not a Tier 1 candidate.

A critical area to audit is the resin drying infrastructure. Many lower-tier suppliers use simple hot air dryers. However, for hygroscopic materials often used in automotive parts, you must insist on dehumidifying dryers. Moisture trapped in the resin can cause structural weaknesses that are invisible to the naked eye but will cause the part to fail under stress.

The "Golden Sample" Protocol

One of the most effective tools we use is the "Golden Sample" approval process. In Vietnam, interpretation of "acceptable quality" can vary. A slight die line might be acceptable in a domestic appliance 4 but rejected in a US automotive interior.

You must implement a strict protocol where signed, physical limit samples are retained at both the factory and your headquarters. These samples define the boundary conditions for cosmetic and dimensional variations. If the factory cannot produce these samples or loses them, their process control is insufficient.

Material Control and Regrind

Another red flag we look for is the misuse of regrind material. While using recycled scrap 5 is common, it must be strictly controlled. Tier 1 standards usually dictate a specific percentage of allowable regrind. We often see suppliers mixing in unauthorized amounts to save costs, which degrades the polymer chains. Your audit must verify that they have a system to track and weigh regrind input to ensure it stays within the agreed specifications.

Table 2: Audit Checklist for Blow Molding Process Control

| Audit Focus Area | What to Look For | Red Flag |

|---|---|---|

| Resin Drying | Dehumidifying dryers with dew point monitors. | Simple hot air dryers for engineering plastics. |

| Parison Control | Automated multi-point parison programming. | Manual adjustment knobs only. |

| Regrind Usage | Scales and logs tracking regrind % per batch. | Unmeasured regrind being tossed into the hopper. |

| Mold Temperature | Thermolators controlling mold temp. | Direct water cooling without temperature control. |

| First Piece Inspection | Documented sign-off at the start of every shift. | No record of setup approval. |

What testing protocols should I implement to verify the durability and finish of the plastic components?

In our testing labs, we frequently find that parts failing in the field passed basic visual inspections. Durability relies on rigorous, destructive testing protocols that simulate real-world stress.

Implement mandatory 100% inline leak testing using pressure or vacuum decay methods to ensure structural integrity. Furthermore, require periodic destructive testing for impact resistance and environmental stress crack resistance (ESCR), alongside material analysis to confirm resin grades match US specifications and contain no unauthorized regrind.

Zero Defects Through Inline Testing

For blow molded parts like fuel tanks 6, air ducts, or fluid reservoirs, a leak is a catastrophic failure. Random sampling is not enough for US Tier 1 standards. We advise implementing automated inline leak testing for 100% of the production volume.

The most reliable methods are pressure decay or vacuum decay testing. These systems can detect microscopic holes that a water bath test might miss. If a Vietnamese supplier suggests manual testing or random checks for critical parts, they are not meeting the zero-defect expectation of the automotive industry.

Material Verification and Traceability

We cannot overstate the importance of material verification. You should require Certificates of Analysis (CoA) for every batch of resin. However, paper can be forged. We recommend performing independent lab testing periodically to confirm the specific resin grades match US specifications.

There is a growing trend in Vietnam 7 towards better traceability. Some pilot programs are even using blockchain to track raw materials. While this is not yet standard, looking for suppliers who have robust lot traceability systems is key. You need to be able to trace a defective part back to the specific hour of production and the specific batch of resin used.

Destructive and Environmental Testing

Beyond leaks, the part must withstand the environment. We recommend establishing a testing schedule that includes:

- Drop Testing: To simulate impact during shipping or vehicle operation.

- ESCR (Environmental Stress Crack Resistance): Crucial for parts exposed to chemicals or detergents.

- Wall Thickness Analysis: Cutting the part to measure thickness at critical corners where thinning occurs during the blowing process.

Table 3: Recommended Testing Protocols for Tier 1 Compliance

| Test Type | Frequency | Method | Purpose |

|---|---|---|---|

| Leak Testing | 100% of production | Pressure/Vacuum Decay | Detects pinholes and structural breaches. |

| Wall Thickness | Every 4 hours / per shift | Ultrasonic Gauge or Sectioning | Ensures corners meet minimum thickness specs. |

| Drop Test | Per batch (random sample) | Free fall from specified height | Verifies impact resistance and weld strength. |

| Material Analysis | Per raw material lot | FTIR / DSC Scan | Confirms resin identity and purity. |

| Visual Inspection | 100% of production | Comparison to Golden Sample | Checks for flash, die lines, and contamination. |

How can I assess if a Vietnamese manufacturer has the technical capacity to meet my strict tolerance levels?

We often challenge suppliers with complex geometries 8 to test their limits. Meeting tight tolerances requires advanced machinery and engineering, not just skilled manual labor or cheap workforce.

Assess technical capacity by evaluating their machinery for multi-point parison programming, which controls wall thickness distribution in complex shapes. Review their mold tooling standards, specifically the use of hardened steel grades, and request process capability studies (Cpk/Ppk) to prove they can statistically maintain tolerances under 0.1mm.

Evaluating Machinery and Parison Control

The technical differentiator between a basic molder and a Tier 1 supplier is often the machinery's ability to control the "parison" (the tube of hot plastic). We look for machines equipped with advanced multi-point parison programming (often 30 to 100 points of control).

This technology allows the machine to vary the thickness of the plastic tube 9 as it is extruded. This is critical for complex shapes where the plastic stretches more in some areas than others. Without this, you will get parts that are too thin in the corners or too heavy in the flat areas. If a supplier cannot demonstrate this capability, they will struggle to meet strict dimensional tolerances.

The Importance of Tooling Standards

The mold itself is the foundation of accuracy. Lower-cost suppliers often use softer steels (like P20) or aluminum to save money. While acceptable for prototyping, these degrade quickly. For high-volume Tier 1 production, we insist on hardened tool steels (like H13 or S136).

You should assess the supplier's in-house tooling capabilities. Do they have the CNC equipment 10 to maintain these molds? A supplier that has to outsource every minor repair will face production delays and quality drift.

Statistical Process Control (SPC)

Finally, do not rely on promises; rely on math. You need to ask for process capability studies. For safety or critical characteristics, US Tier 1s typically demand a Cpk and Ppk value exceeding 1.67 during the pilot phase (based on at least 125 samples).

In serial production, this should not drop below 1.33. These numbers prove that the process is stable and capable of consistently producing parts within tolerance. If a Vietnamese supplier looks confused when you ask for "Cpk data," they are not ready for your business. We have seen that suppliers who track this data reduce their PPM (parts per million defects) significantly, often by 50% or more, aligning them with the expectations of major automotive contracts.

Conclusion

To successfully source blow molding parts from Vietnam for US Tier 1 supply chains, you must enforce a rigorous qualification process. This involves verifying IATF 16949 certification, auditing for advanced process controls like parison programming, and mandating statistical evidence of capability (Cpk > 1.33). By validating these technical and quality milestones, you can secure a reliable, high-quality partner.

Footnotes

1. International standard for quality management systems. ↩︎

2. Global quality management system standard for the automotive industry. ↩︎

3. Environmental, social, and governance factors used to measure sustainability. ↩︎

4. Definition and standards for household electrical machines. ↩︎

5. Information on plastic recycling and the use of scrap materials. ↩︎

6. EPA information regarding fuel systems and environmental standards. ↩︎

7. General information about the country’s developing industrial landscape. ↩︎

8. Replaced broken commercial link with stable Wikipedia link relevant to the design of complex automotive parts. ↩︎

9. Apple’s commitment to precision manufacturing and material quality. ↩︎

10. ISO standards for industrial automation and manufacturing systems. ↩︎