Optimizing logistics for custom metal parts can be a game-changer when it comes to improving delivery times, reducing costs, and ensuring quality. When sourcing parts from overseas, the complexity of the logistics process often introduces delays and additional costs. By focusing on logistics optimization1, companies can enhance their supply chain efficiency and improve customer satisfaction.

Optimizing logistics for custom metal parts requires implementing best practices, minimizing lead times and costs, and ensuring end-to-end visibility. A streamlined logistics process can provide significant competitive advantages.

In this article, we’ll explore how businesses can manage their logistics more effectively, reduce costs, and make sure their custom parts arrive on time and in perfect condition.

What Are the Best Practices for Managing Logistics of Custom Parts?

Managing logistics for custom parts requires a strategic approach that includes planning, collaboration, and flexibility. By following best practices, businesses can streamline the process, reduce delays, and control costs.

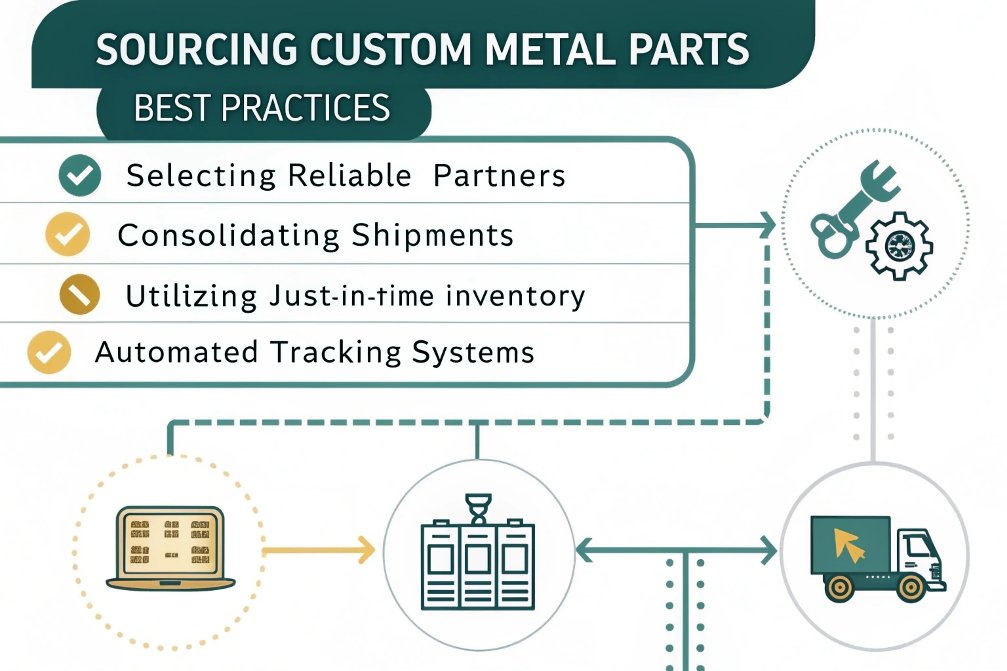

When it comes to logistics, there are several best practices that can make a significant difference in how efficiently custom metal parts are sourced, transported, and delivered. Here are some key strategies:

1. Select the Right Shipping Partners

One of the first steps to optimizing logistics is to choose reliable shipping partners2 that understand the specific needs of custom parts. Work with freight forwarders, carriers, and logistics providers who have experience in handling high-value, time-sensitive shipments.

- Freight forwarders specializing in customized metal parts can help you navigate complex logistics.

- Experienced partners help avoid common delays or damage during transportation.

2. Consolidate Shipments

Where possible, consolidate shipments from different suppliers or factories into one shipment to save on transportation costs. Bulk shipping not only reduces costs but also minimizes the complexity of managing multiple deliveries.

- Consolidating orders into one shipment can reduce shipping fees.

- Fewer shipments to manage mean simpler logistics and less risk of errors.

3. Use Just-in-Time (JIT) Inventory

Implementing a JIT inventory system means ordering parts based on current demand rather than forecasting. This minimizes the need for large warehouses and allows you to order only what’s necessary, optimizing your cash flow and reducing the need for excess storage.

- JIT inventory systems reduce the need for excessive warehousing and help optimize inventory.

- Less stock to manage can lower overall logistics costs.

4. Implement Automated Tracking Systems

Using automated systems to track shipments in real-time ensures that all stakeholders are aware of where the custom parts are at any given time. This improves communication and allows for better decision-making when things go wrong.

- Real-time tracking enables proactive issue resolution.

- Better visibility allows more precise coordination between suppliers and customers.

| Best Practice | Description | Key Advantage |

|---|---|---|

| Choose Reliable Partners | Work with experienced logistics providers | Ensures timely and safe delivery of parts |

| Consolidate Shipments | Combine multiple shipments into one | Saves on shipping costs and reduces complexity |

| Use Just-in-Time Inventory | Order based on current demand, not forecasts | Reduces storage costs and inventory overhead |

| Automated Tracking | Implement real-time tracking systems | Enhances visibility and helps resolve issues quickly |

How Can You Minimize Lead Times and Costs for Custom Parts Shipping?

Minimizing lead times and shipping costs is critical for staying competitive in today’s global market. Companies must be strategic about their logistics processes to achieve the best balance between speed and cost.

Reducing lead times and shipping costs are two of the most important objectives when it comes to logistics optimization. Here are some strategies to help companies meet these goals:

1. Choose the Right Transportation Mode

Selecting the best transportation method for your custom parts depends on your priorities. Air freight is faster but more expensive, while sea freight is more cost-effective but takes longer. Balancing these options based on urgency and budget can help minimize both lead times and costs.

- For faster delivery, air freight may be a good option despite higher costs.

- For cost savings, sea freight is a more affordable option for less time-sensitive shipments.

2. Optimize Routing

Choose the most efficient shipping routes and transportation methods based on current traffic patterns, weather conditions, and port congestion. Using advanced logistics software can help identify the fastest and most affordable routes in real-time.

- Optimizing routes reduces delays and ensures parts reach their destination on time.

- Using logistics software for route planning can cut down unnecessary transportation time.

3. Negotiate Better Shipping Rates

Negotiating shipping rates with your logistics providers can lead to better cost control, especially when working with large or regular shipments. Volume discounts, longer-term contracts, or relationships with specific freight companies can help reduce overall shipping costs.

- Long-term contracts or high-volume shipments often result in lower per-unit shipping costs.

- Negotiating directly with carriers can sometimes offer more flexibility on pricing.

4. Strategic Inventory Locations

Having strategically located warehouses or distribution centers can reduce shipping time, as custom parts will already be closer to your customers. By storing parts in key markets or regions, you can minimize shipping distances and expedite delivery.

- Multiple warehouses in key locations can speed up deliveries to clients.

- Strategically located inventory can lower the cost of last-mile delivery.

| Strategy | Description | Key Outcome |

|---|---|---|

| Choose the Right Transport Mode | Air freight for speed, sea freight for cost | Balance speed and cost based on needs |

| Optimize Routing | Use advanced software to identify the best routes | Reduces lead time and delays |

| Negotiate Shipping Rates | Work with providers for better rates | Reduces shipping costs over time |

| Strategic Inventory Locations | Use warehouses in key regions to reduce delivery time | Faster deliveries and lower last-mile costs |

Why Should You Prioritize End-to-End Visibility in Custom Parts Logistics?

End-to-end visibility is critical for ensuring that the logistics process runs smoothly from start to finish, particularly when dealing with custom parts. It allows businesses to monitor progress, handle issues quickly, and maintain control over the entire supply chain.

Having full visibility over the logistics process provides multiple advantages, helping businesses to be proactive, minimize risks, and optimize performance. Here’s why prioritizing end-to-end visibility is crucial:

1. Real-Time Monitoring and Proactive Problem-Solving

End-to-end visibility allows businesses to monitor the progress of shipments in real-time, giving them the ability to quickly address any delays, customs issues, or logistical challenges. This proactive approach minimizes disruptions and ensures smoother operations.

- Real-time updates help address problems before they escalate.

- Businesses can quickly implement corrective actions for any supply chain issues.

2. Better Communication Across the Supply Chain

Visibility enables all parties—suppliers, manufacturers, freight forwarders, and customers—to stay informed about the status of shipments. This helps avoid miscommunication and confusion, improving collaboration across the supply chain.

- Improved communication reduces misunderstandings and delays.

- Collaboration with suppliers and logistics partners becomes more streamlined.

3. Enhanced Decision-Making

Having access to real-time data means companies can make more informed decisions regarding logistics. Whether it’s rerouting shipments, adjusting delivery schedules, or changing suppliers, better visibility helps companies optimize their supply chain for maximum efficiency.

- Access to real-time data empowers businesses to make timely and informed decisions.

- Improved decision-making leads to more efficient use of resources.

4. Risk Management

With full visibility of the supply chain, businesses can identify risks such as delays, damaged goods, or unexpected costs. This visibility allows for quick mitigation and ensures that risks are managed before they become major issues.

- Quick identification and mitigation of risks help prevent costly disruptions.

- Allows businesses to react quickly to changing conditions and minimize supply chain risks.

| Benefit | Description | Key Advantage |

|---|---|---|

| Real-Time Monitoring | Track shipments and handle issues quickly | Proactively addresses delays or issues |

| Better Communication | Improve coordination between parties | Reduces confusion and fosters collaboration |

| Enhanced Decision-Making | Access to data for faster, informed decisions | Optimizes logistics performance |

| Risk Management | Identify risks early and address them | Minimizes disruptions and costs |

Conclusion

Optimizing logistics for custom metal parts involves choosing the right partners, consolidating shipments, reducing lead times, and ensuring end-to-end visibility. By implementing these strategies, businesses can improve efficiency, reduce costs, and ensure timely delivery of high-quality parts. The key is to maintain control over the entire logistics process, ensuring that every stage, from production to delivery, is seamless and well-managed.