If you’re like me, you’ve probably questioned whether Vietnam can really deliver when it comes to the precision and quality the U.S. market demands. I’ve heard concerns—I’ve had them too.

Yes, Vietnam’s manufacturing quality can meet U.S. standards—if you choose certified factories, specify standards in contracts, and ensure independent inspections before shipment. The key is process control, not just price.

So how do you make sure what you receive is up to spec? Let’s break it down step by step.

What quality certifications do Vietnamese factories hold?

When I first started sourcing from Vietnam, my biggest concern was: how do I know the factory has real quality systems in place?

Many Vietnamese manufacturers hold internationally recognized certifications like ISO 9001 for quality management 1 and ISO 14001 for environmental management 2. Welding-specific factories often hold ISO 3834. These standards align closely with what American buyers expect.

Vietnam has been catching up fast in terms of compliance. Some factories even go a step further by acquiring industry-specific certifications, like IATF 16949 for automotive or ISO 13485 for medical devices.

Key Quality Certifications

| Certification | Scope | Common Use |

|---|---|---|

| ISO 9001 | Quality Management Systems | General manufacturing |

| ISO 14001 | Environmental Management | Eco-conscious operations |

| ISO 3834 | Welding Quality | Structural steel, pressure vessels |

| IATF 16949 | Automotive Quality | Auto parts manufacturing |

| ISO 13485 | Medical Device Quality | Medical-grade parts |

While certifications don’t guarantee perfection, they do show a company has formalized procedures and audit trails. I always insist on seeing valid, up-to-date certificates during factory qualification.

How do U.S. buyers verify product compliance?

One mistake I made early on was assuming the supplier would "just know" my standards. That didn’t end well.

U.S. buyers verify product compliance by clearly stating international standards—like ASTM, ASME, ANSI, or ISO 3—in the drawings and contracts. Pre-shipment inspections, certificates of conformity, and documented testing results are then used to ensure alignment.

Buyers must take the lead in communication. I always make sure our clients include the exact testing method, acceptance criteria, and measurement tools in the contract.

Common U.S. Standards Referenced

| Standard | Description | Application |

|---|---|---|

| ASTM A36 | Standard for structural steel | Construction parts |

| ASME B31.1 | Piping codes | Industrial equipment |

| ANSI B46.1 | Surface texture | Machined components |

| ISO 2768 | General tolerances | Custom machined parts |

| MIL-STD | Military-grade specs | Aerospace, defense |

Pre-shipment documentation typically includes:

- Material certificates

- Dimensional inspection reports

- Surface treatment records

- Test results (e.g., hardness, tensile)

A detailed checklist of what the supplier must provide can save you from big headaches down the line.

Are Vietnamese machining tolerances as precise as U.S. needs?

I’ve heard this question a hundred times from buyers. It’s a fair concern, especially if you’ve dealt with suppliers who misunderstood tight tolerances.

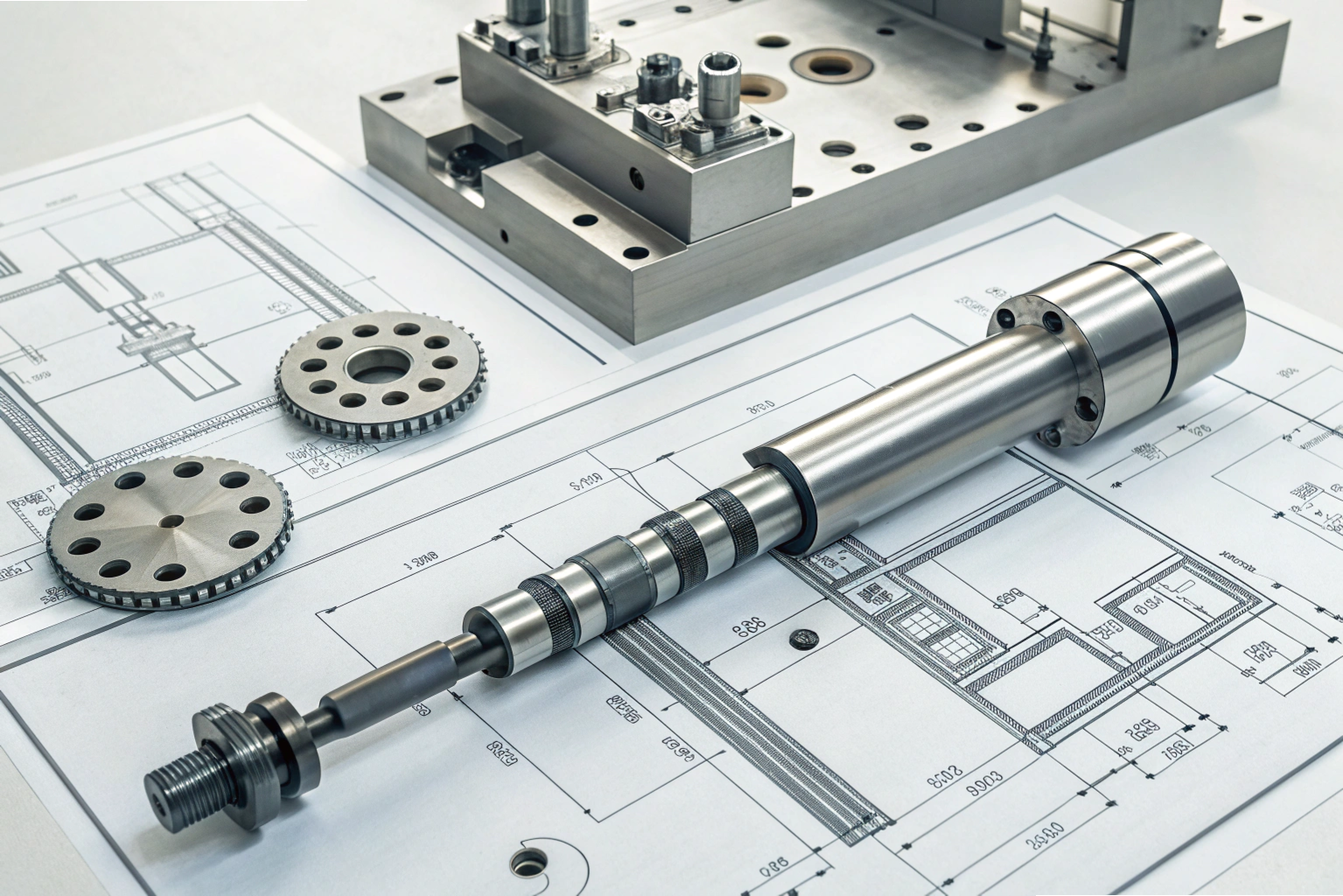

Yes, top Vietnamese factories routinely achieve tolerances of ±0.02 mm to ±0.05 mm in CNC machining 4, which aligns with U.S. industry needs. They use 3-axis, 4-axis, and even 5-axis machines for precision parts.

Precision depends on both machinery and process control. Vietnam has invested heavily in modern CNC centers, CMMs (coordinate measuring machines), and skilled machinists trained to global standards.

Tolerance Capabilities by Process

| Process | Typical Tolerance Range | Notes |

|---|---|---|

| CNC Milling | ±0.02 – ±0.05 mm | Common across well-equipped shops |

| CNC Turning | ±0.01 – ±0.03 mm | Tight tolerances achievable |

| Sheet Metal | ±0.2 – ±0.5 mm | Depends on material and method |

| Laser Cutting | ±0.1 mm | Consistent, fast process |

| Welding | ±1.0 – ±2.0 mm | Controlled by jigs and fixtures |

Make sure to define:

- The tolerance zone

- Which features are critical

- Any surface finish requirements

- Measuring tools to be used (CMM, caliper, microscope, etc.)

The clearer you are, the better the outcome.

What inspection services ensure quality before shipment?

Here’s what I learned the hard way—if you skip inspections, you’re just hoping for the best. That’s not a strategy.

Buyers ensure quality by scheduling mid-production and pre-shipment inspections 5. These often include dimensional checks with CMMs, surface roughness tests, hardness or tensile tests, and even 100% inspection on critical features.

Vietnam has a robust network of third-party inspectors and testing labs. Names like SGS, TUV, and Intertek 6 are active in the country. You can also hire engineering-based inspection services through supply chain companies like ours.

Common Inspection Stages

| Stage | Purpose | Typical Methods |

|---|---|---|

| Incoming QC | Verify raw materials | Spectrometer, visual check |

| In-Process QC | Prevent defects early | IPQC reports, operator logs |

| Final QC | Confirm before shipment | CMM, hardness, appearance |

| Pre-Shipment | Customer-specific | AQL sampling, spec matching |

During pre-shipment inspections, I always recommend:

- Using AQL 1.0 or stricter for critical parts

- Requesting video/photo documentation

- Adding special tests for unique features (e.g., coating thickness, thread gauge)

Inspections are your last line of defense. Skipping them is like running a factory on faith.

Conclusion

Vietnamese factories can meet U.S. standards—if you work with the right partners, define specs clearly, and never skip inspections. That’s how we protect every order.

Footnotes

Rawlplug Vietnam’s ISO 9001 certification proves quality systems and traceability. ↩ ↩

VPIC Group’s ISO 14001 certification highlights eco-friendly compliance in Vietnamese manufacturing. ↩ ↩

Browse ASTM international standards widely used in U.S. manufacturing and contracts. ↩ ↩

Valo Vietnam offers sub-±0.02 mm CNC tolerances, suitable for critical U.S. precision components. ↩ ↩

QIMA provides on-site inspections and lab tests for verifying Vietnam manufacturing before shipment. ↩ ↩

Intertek offers third-party inspection and compliance verification across Vietnam’s industrial zones. ↩ ↩