I’ve seen too many cases where buyers assume “low cost = low risk” — only to be hit with quality disasters later.

Yes — Vietnam’s metal fabrication capabilities have matured enough that they can meet U.S. tolerances and standards — as long as you pick the right factory, define stringent specs, and enforce QA.

But don’t assume “Vietnam = U.S. quality” by default. You’ll need technical due diligence and strong process control to make it work.

What CNC tolerances do U.S. buyers require?

I still remember a client losing thousands because a CNC shop overseas couldn’t hold ±0.005" tolerance on a small shaft — they thought “close enough” was good enough.

U.S. buyers typically expect tolerances in the range of ±0.001" to ±0.005" (0.025 mm to 0.125 mm) for most machined parts — narrower in aerospace, medical, or critical fits.

Typical CNC Tolerances by Application

| Application | Typical Tolerance (inch) | Metric (mm) | Notes |

|---|---|---|---|

| General mechanical parts | ±0.003" to ±0.005" | ±0.076 to ±0.127 | Suitable for general machinery and industrial parts |

| Press/tight fits | ±0.001" to ±0.002" | ±0.025 to ±0.051 | For bearings, shafts, couplings |

| Aerospace/medical parts | ±0.0005" to ±0.001" | ±0.013 to ±0.025 | Requires high-end equipment and controlled environments |

| Geometric tolerances | ±0.001" | ±0.025 | Flatness, parallelism, perpendicularity |

Vietnam’s best CNC shops — like SJ CNC or VMF Precision — use 4- and 5-axis machining centers 1, CMMs, and digital inspection tools. They achieve tolerances as tight as ±0.0001" (0.0025 mm) in critical areas. But this capability is not standard — it must be audited, confirmed, and validated with test runs before mass production.

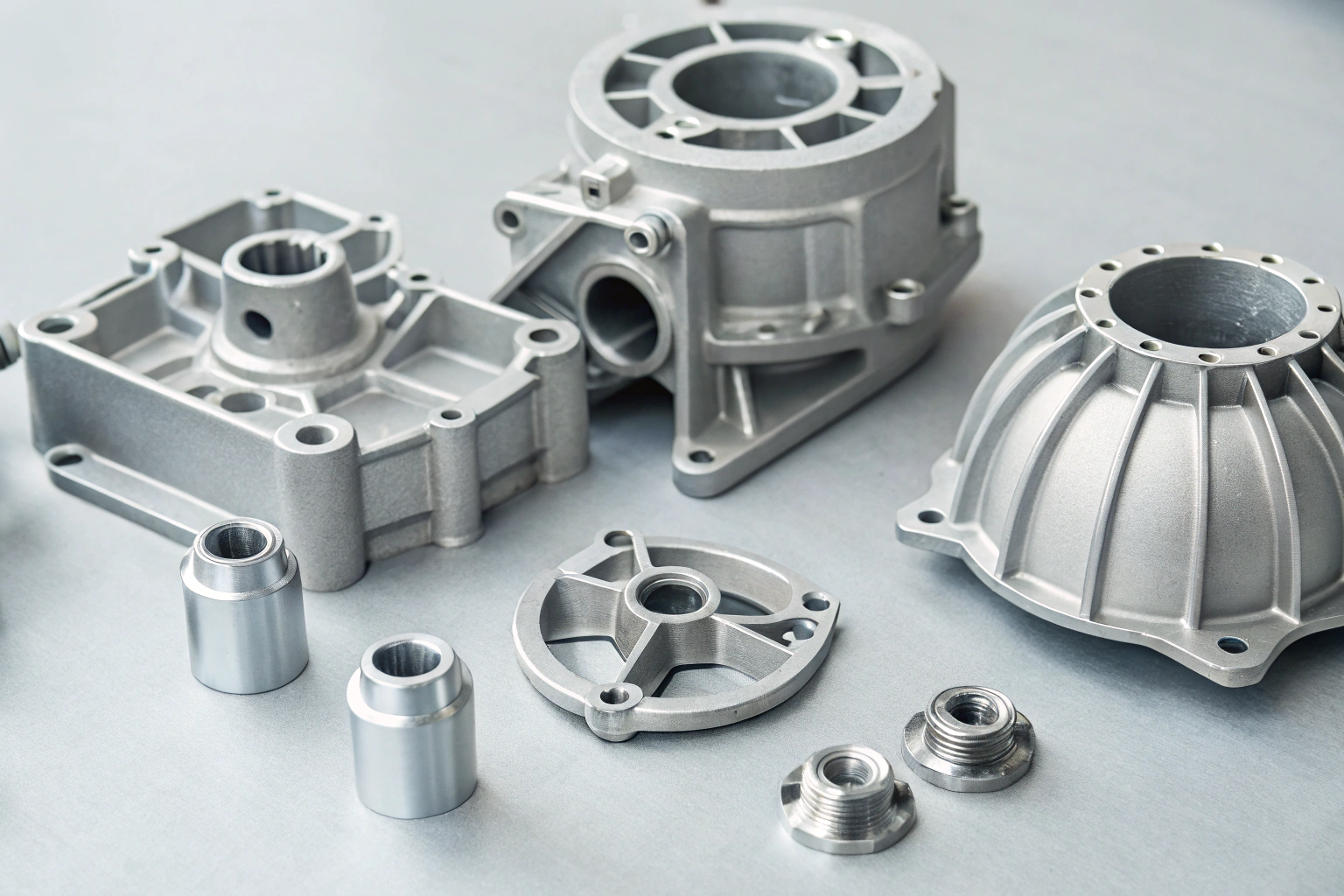

How mature are casting methods in Vietnam?

Vietnam’s foundry sector has evolved significantly over the past decade. Many foundries now run die casting, investment casting, sand casting, and secondary machining within the same facility.

Yes — casting in Vietnam is mature enough for many U.S. applications, especially in aluminum, zinc, and nonferrous metals, though some gaps remain in large-volume ferrous or aerospace-grade parts.

Maturity of Vietnamese Casting Processes

| Casting Type | Maturity Level | Common Materials | Typical U.S. Uses |

|---|---|---|---|

| Die Casting | High | Aluminum, Zinc | Automotive housings, lighting parts |

| Investment Casting | Medium-High | Stainless, Carbon Steel | Aerospace, valves, medical parts |

| Sand Casting | Medium | Cast Iron, Steel, Aluminum | Large industrial, marine, pump housings |

| Shell Mold | Medium | Steel, Ductile Iron | Engine blocks, gear housings |

| Hot Forging + Machining | Medium-High | Steel, Alloys | Axles, shafts, structural parts |

The better facilities apply casting simulation software 2, maintain internal QC labs, and support in-house post-processing (machining, heat treatment). Several (e.g., VPIC, IDEA Group) serve North American OEMs with consistent quality and certified output.

Is stamping quality consistent with U.S. standards?

Stamping in Vietnam has reached impressive levels, especially in sheet metal forming, enclosures, brackets, and housings. But “consistent with U.S. standards” depends heavily on tooling, die maintenance, material control, and press stability.

Yes — stamping quality in Vietnam can meet U.S. standards for many applications, but consistency is the key challenge.

Well-managed Vietnamese stamping lines use servo presses 3 (up to 500 tons), progressive dies, and in-line quality checks. Suppliers like VPIC and JSK Stamping offer U.S.-comparable outputs, provided buyers validate Cp/Cpk levels and die control systems.

Risks come from tool wear, poor die changeover discipline, or inconsistent coil stock. I always inspect multiple production stages — not just samples — and require material traceability systems 4 per batch.

Can Vietnamese welding pass U.S. certification tests?

This is often the most feared process. Many buyers worry: “If the weld fails, liability is mine.”

Yes — Vietnamese welders and fabricators can pass U.S. welding certifications, but only when supported by certified procedures, skilled technicians, and formal NDT protocols.

Common Welding Standards and Certifications in Vietnam vs U.S.

| Standard/Cert Name | Scope | Recognized in U.S.? | Vietnamese Availability |

|---|---|---|---|

| ISO 3834 | Welding QMS (fusion welding) | Yes | Widely adopted |

| ASME Section IX (WPS/WPQ) | Procedure and welder qualification | Yes | Some factories have it |

| AWS CWF/CRAW/CWS | Fabricator/Welder Certification | Yes (OEM-approved) | Limited but growing |

| ISO 9712 (NDT) | Weld testing and inspectors | Yes | Available via 3rd party labs |

| EN ISO 15614 | Procedure test for welding | Indirect | Some overlap via ISO adoption |

Vietnam’s welding sector is growing stronger through AWS certification programs 5. ISO 3834 certification is now widespread in larger metal shops, and select facilities now offer robotic MIG/TIG welding under certified WPS/WPQ control.

To ensure quality, I ask for the WPS and WPQ documentation 6 and evidence of NDT (radiographic or ultrasonic) for representative samples — and I always insist on pre-shipment weld inspections.

Conclusion

Vietnam’s CNC, casting, stamping, and welding capabilities have caught up with global norms — but not all factories are equal. Choose ISO-certified suppliers 7, demand U.S.-standard documentation, and verify process control with third-party inspections 8.

With the right supplier selection and QA, importing from Vietnam 9 can deliver cost savings without compromising compliance with U.S. manufacturing standards 10.

Footnotes

1. Explanation of 5-axis CNC machining and its precision benefits. ↩︎

2. Casting simulation software improves defect prediction and quality. ↩︎

3. How servo press technology enhances metal stamping quality. ↩︎

4. Why material traceability is essential for quality assurance. ↩︎

5. AWS certification pathways for welders and fabricators. ↩︎

6. Role of WPS and WPQ in welding quality control. ↩︎

7. Importance of ISO certification for supplier reliability. ↩︎

8. Independent product inspections for manufacturing quality assurance. ↩︎

9. U.S. trade guide to doing business with Vietnam. ↩︎

10. U.S. NIST standards supporting manufacturing compliance. ↩︎