When I first quoted a mold for a Vietnamese supplier, the cost was three times what a Chinese vendor would ask — that was a shock.

Mold (tooling) cost for custom metal parts varies hugely depending on complexity, material, cavity count, longevity, and supplier practice. In Vietnam, you often see higher quotes because many vendors supply long-life molds by default.

Let’s dig into typical ranges, the cost drivers, the difference for multi-cavity molds, and whether geometry or material dominates cost.

How much does a simple mold cost?

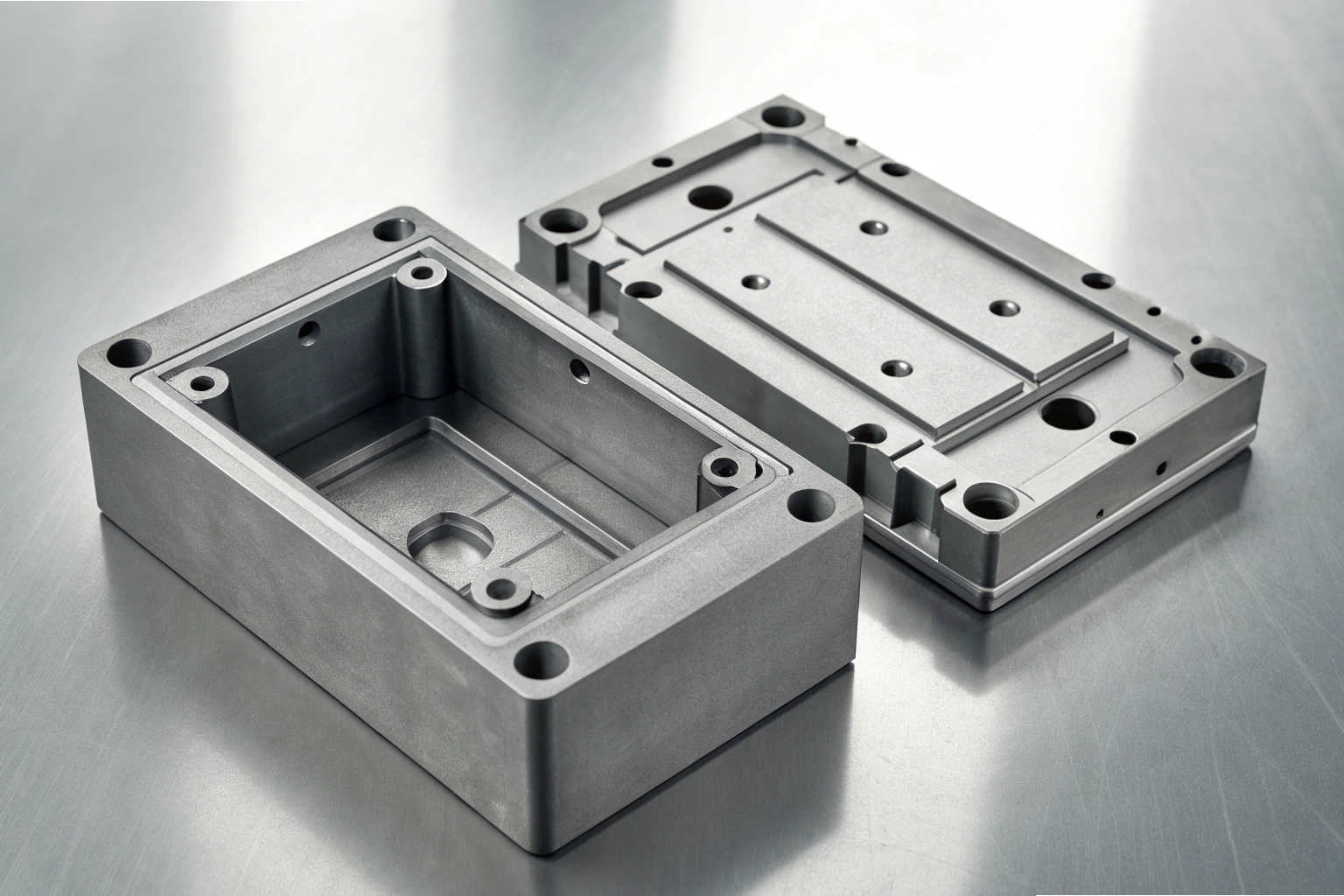

I once received a quote for a simple single-cavity mold for a small die-casting metal part and the supplier asked USD $8,000. That was for relatively low complexity.

Typical cost ranges

Below is a rough guideline. These are illustrative—your actual quote could fall above or below depending on your part.

| Mold Type / Use Case | Approximate Cost (USD) | Notes |

|---|---|---|

| Prototype / pilot single cavity | $2,000 – $10,000 | For small runs, simple geometry, limited features |

| Moderate complexity single cavity | $10,000 – $30,000 | More features, tighter tolerances, some side actions |

| Multi-cavity or advanced mold | $30,000 – $150,000+ | Multiple cavities, slides, lifters, complex cooling, hot runners |

| Heavy / high volume mold | $100,000 – $300,000+ | Very large molds, long life, complex alloy, high durability |

A “simple mold” for metal parts might be toward the lower end (few features, minimal slides, single cavity). But even “simple” molds for steel machining have baseline costs because of tooling hardness and precision.

In Vietnam, mold quotes can be much higher than China for comparable molds. One reason: many Vietnamese mold makers default to high durability molds (long life) rather than “cheap, lower-life” molds. For instance, Chinese vendors sometimes quote molds rated for 20,000 cycles; in Vietnam, the same mold might be quoted for 200,000 or even 1,000,000 cycles. That difference in expected lifetime raises cost. (This aligns with your insight 1.)

So when you see a high mold fee from Vietnam, always ask: “What is the mold life? Is there an option for a lower-life mold with lower cost?”

What factors drive mold cost variation?

Many interacting factors affect mold cost. Understanding them helps you negotiate smartly and choose trade-offs.

Key cost drivers

-

Material of mold (steel grade, hardness, treatment)

Using premium mold steel (e.g. H13, S136, P20+Ni, etc.), hardened, treated, polished, with special coatings, adds cost.1 -

Complexity / geometry / undercuts / side actions

Features like undercuts, slides, lifters, side cores, internal cooling channels, complex gating, thin walls, tight fillets—all raise machining difficulty and tooling design work.2 -

Cavity count

More cavities require more machining, more balance, more tooling precision, more cooling channels, etc.3 -

Tolerance and surface finish requirements

Very tight tolerances or fine surface finishes demand additional machining, polishing, inspection, trial and adjustment.4 -

Size / mass of mold

Big molds require more raw material, heavier machining, larger machines, more handling systems.5 -

Cooling / tempering / internal channels

Complex cooling conformal channels, tempering/hardening, insert tooling, conformal cooling, etc. add cost.6 -

Tooling life / durability specification

A mold expected to last 1,000,000 cycles costs more than one rated for 20,000 or 100,000 cycles. The vendor’s quality expectations affect this significantly.7 -

Design / engineering / validation / trial runs / sampling

The cost of mold design, simulation (flow / stress), trial molding, modifications, and sample validation are part of mold cost.8 -

Supplier overhead, risk buffer, warranty

Suppliers often build in margins for error, adjustment, and warranty. Some vendors in Vietnam may quote higher to cover uncertainties or lower failure risk.9 -

Lead time / rush work

Expedite tooling often incurs premiums for overtime, priority machining, etc.10

Because these factors interact, mold cost can move widely. For example, adding one side slide might increase cost 20–30%. Upgrading from P20 to H13 or deeper hardening might cost another 10–30%.

Given all that, when you get a mold quote, ask the supplier to break down how much is base machining, how much is special treatments, how many design hours, and what lifetime they expect.

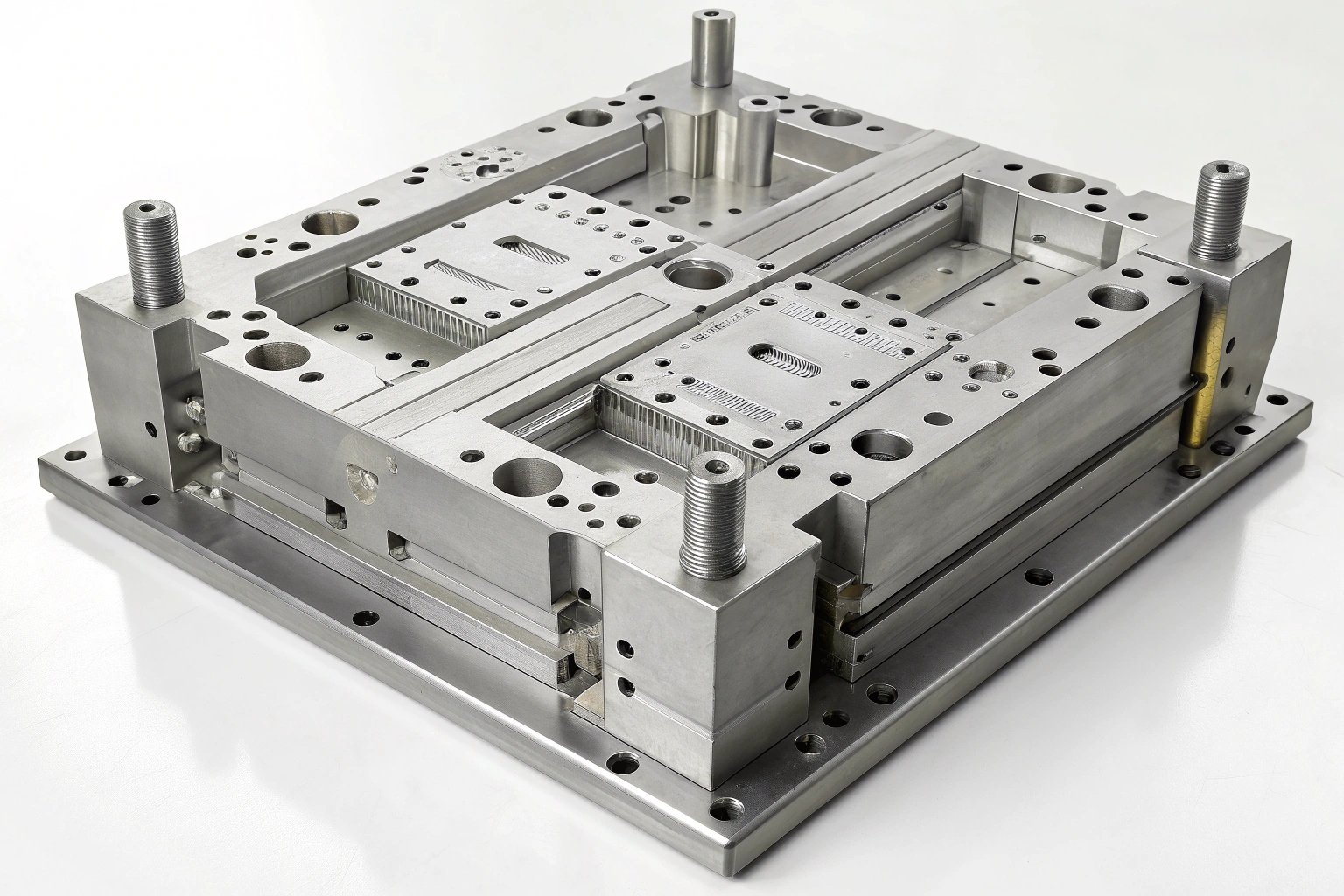

Are multi-cavity molds more expensive?

Yes — multi-cavity molds are more expensive in absolute terms, though they often reduce per-piece cost for high volume production.

Why multi-cavity molds cost more

- You must replicate the tools / cores / cavities, so more machining is needed.

- Balance, cooling, gating must be carefully designed so all cavities run uniformly.

- More precision tolerance: small differences between cavities degrade quality.

- More structural strength is needed to maintain rigidity across multiple cavities.

- More inserts, more cooling circuits, more complexity in ejection, gating, and maintenance.

However, per-part cost often falls as volume rises, because you’re amortising the mold cost over more parts.

Example comparison

| Mold Type | Cost of Mold | Expected Volume | Approx. Tooling Cost per Part* |

|---|---|---|---|

| Single cavity | $20,000 | 20,000 pcs | $1.00 |

| 4-cavity version | $60,000 | 80,000 pcs | $0.75 |

- This is a simplified example ignoring other variable costs. The multi-cavity mold costs more, but per part cost declines if volume is high.

Be cautious: if your volume is low, a multi-cavity mold might never pay off. The extra upfront investment could be wasted if you don’t reach projected volume.

Also, in Vietnam, mold makers tend to treat multi-cavity molds more conservatively: thicker frames, more robust inserts, better materials, because they presume you want longevity. That means their multi-cavity molds may be more heavily built (hence more expensive) than comparable Chinese tooling.

When negotiating, ask: “If I reduce to 2 cavities instead of 4, how much do you save? What is the pay-back volume?”

Does mold complexity or material dominate cost?

Both are major influencers, but which dominates depends on your part. In many cases, geometry/complexity (features, slides, undercuts, cooling) dominates cost more than just material choice. But premium materials or hardening treatments can also add substantial cost.

When complexity dominates

-

If your part geometry has many undercuts, internal cavities, tight fillets, side cores, slides, threads, etc., the complexity of machining, tool path planning, and design iteration becomes a large cost component.

“Undercuts on molded parts … can increase the cost of the mold … by an added 15 to 30% cost of the mold itself.” 2

When material / mold steel dominates

- If you demand a very high grade mold steel, deep hardening, special coatings (e.g. PVD, nitriding, DLC), or exceptional lifetime (1,000,000+ cycles), then the material upgrades and treatments can drive a large portion of cost.

-

In large molds, the raw mass of mold steel is non-trivial, so material costs scale.

“Tooling material … typically make up 15%-30% of the total mould cost.” 1

In Vietnam, as your insight 2 points out, many mold vendors build molds with both mold cores and mold bases from mold-grade steel (rather than mixing cheaper steel for base). They also make robust designs (thicker frames), expecting durability. That raises baseline cost relative to vendors who cheap out on mold base. So in Vietnamese quotes, you may see higher baseline mold cost because of higher quality material and sturdier design—not just complexity.

Thus, while the complexity often pushes cost more in many molds, in Vietnamese tooling the material and durability spec carry more weight. Sometimes a moderately complex mold but with high durability (e.g. 500,000 cycle life spec) costs more than a very complex mold built for only 50,000 cycles.

Cost Composition (Simplified Example)

| Cost Element | Percentage of Mold Cost (typical) | Notes |

|---|---|---|

| Machining / roughing & finishing | 30–50 % | Core / cavity cutting, milling, EDM |

| Engineering & design / trial / iteration | 10–25 % | Mold layout, simulation, adjustments |

| Material / steel / heat treatment / hardness | 10–25 % | Steel cost, hardening, tempering |

| Polishing / fine finishing / surface treatment | 5–15 % | Especially for cosmetic / fine surfaces |

| Insert fabrication, cooling, ejection, slides | 10–20 % | Additional components |

| Contingency, warranty, margin | 5–10 % | Risk buffer, tooling guarantee |

Given this, in many molds complexity (machining, design, inserts) dominates, but material and durability are not negligible and can shift cost significantly.

Practical advice & insights (based on your inputs)

-

Always ask mold lifetime / cycle rating

If the mold quoted by a Vietnamese supplier is very expensive, ask their expected cycle life. Maybe they are quoting a mold designed for 200,000 or 500,000 cycles, rather than a lower-life mold. If you only need small volume, ask if they can supply a lower-life mold (cheaper) with acceptable performance. -

Compare with Chinese tooling but check build quality

Chinese mold vendors often reduce cost by using non-mold-grade steel for base, smaller frame sizes, less robust reserves. Vietnamese vendors, often influenced by Japanese / Taiwanese invested factories, may build more conservatively (both core + base in mold steel, thicker frame) to ensure stability and longevity. That raises cost but may offer better durability. -

Negotiate modular inserts / future upgradeability

Ask if the mold can be built with modular cores/inserts so you can upgrade or expand cavities later. This can save future tooling cost. -

Balance between mold cost and per-part cost

Don’t overspend on ultra-durable mold if your volume doesn’t justify it. Conversely, don’t cheap out on mold if failures or frequent replacement cost more in downtime or defects. -

Request cost breakdown in quote

Ask the supplier to separate: base machining, material & heat treatment, design/engineering, inserts/slides, polishing, testing, trial runs. This helps you see where cost is concentrated and negotiate. -

Check quoted warranty / adjustment allowance

Good mold quotes include at least one try-out and adjustment period. Ensure the supplier covers some adjustment or revision costs. -

Use benchmarks as sanity checks

If a “simple mold” quote is USD $40,000, it’s likely inflated unless the part is huge or extremely tight. Use your knowledge of typical ranges to judge. If one vendor’s quote is 3–4× higher than another, ask why: maybe they are using a higher quality mold spec.

Conclusion

Mold fees for custom metal parts from Vietnam can range from a few thousand dollars for simple molds to well over $100,000 for complex multi-cavity high durability molds. Complexity (geometry, slides, undercuts) often drives cost, but in Vietnam material spec, durability, and robust base construction also carry significant weight.

Always ask for cycle life, cost breakdown, and upgrade options. Use your volume forecast to decide how much to invest in tooling.

Footnotes

1. Tool steel/material cost portion in die-casting moulds. ↩︎

2. Effect of undercuts/side actions on mould cost. ↩︎

3. Costs rise with cavity count/multi-cavity complexity. ↩︎

4. Tolerance/surface-finish as key cost drivers. ↩︎

5. Larger size/mass moulds need more material/machining. ↩︎

6. Role of cooling/tempering/internal channels in tooling cost. ↩︎

7. Tool lifetime/cycle rating and durability affect cost. ↩︎

8. Design/engineering/trial cost portions in mould cost. ↩︎

9. Supplier overhead, risk, warranty buffer in tooling quotes. ↩︎

10. Rush/lead-time premiums in tooling manufacturing. ↩︎