When comparing Vietnam and China for manufacturing, logistics plays a crucial role in cost efficiency and supply chain management. But how do the logistics costs and methods differ between these two manufacturing powerhouses?

International logistics between Vietnam and China differ significantly, with Vietnam generally having higher shipping costs and fewer logistics options compared to China.

In the following sections, we will dive deeper into the costs and logistical considerations of manufacturing in both countries to help you make a more informed decision.

How much does it cost to ship from Vietnam vs China?

Manufacturing costs can vary greatly based on numerous factors such as labor, materials, and, of course, logistics. But when it comes to international shipping, the costs can be a deciding factor.

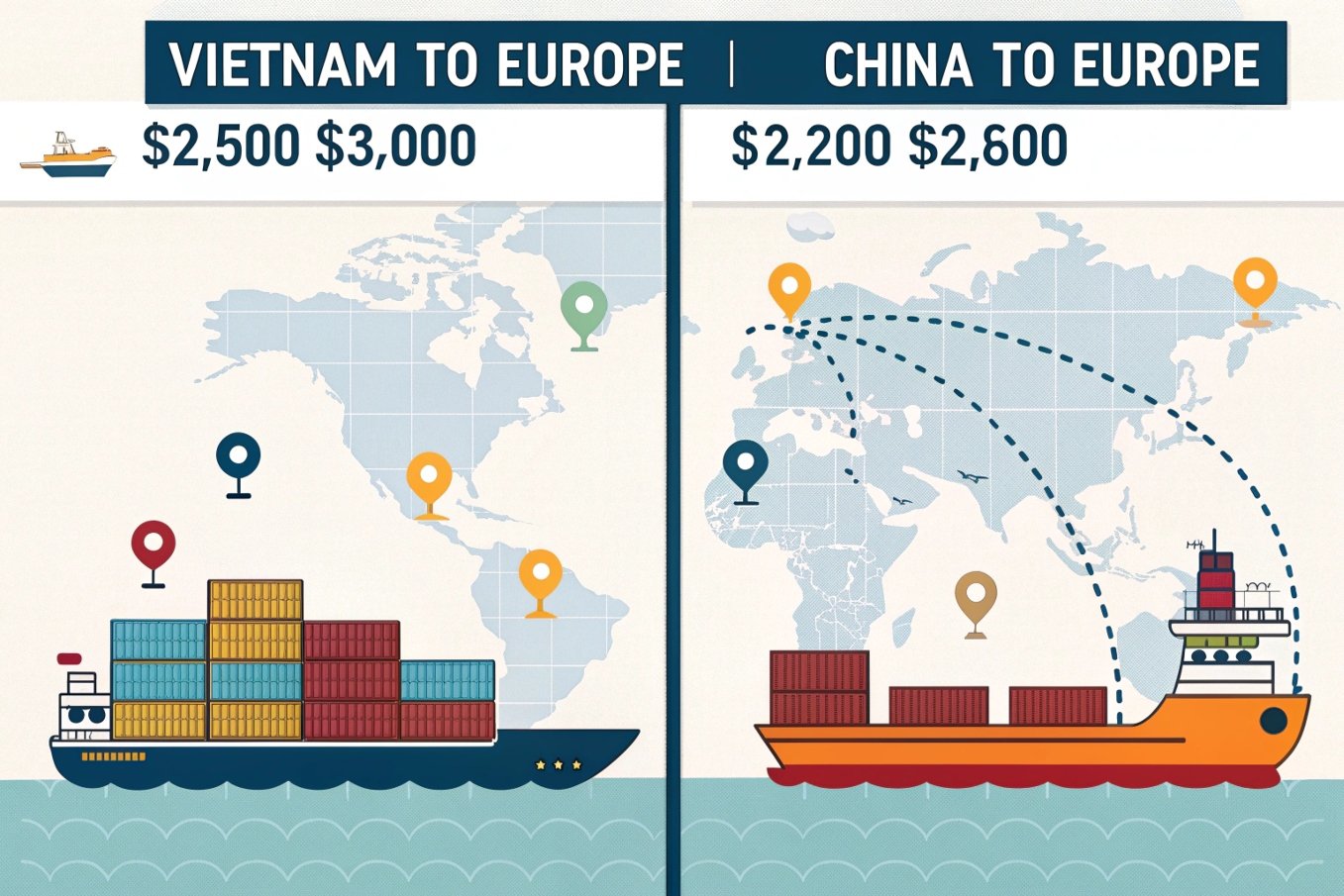

Shipping costs from Vietnam are generally 10% higher than from China to Europe and North America due to the differences in port infrastructure and scale of operations.

One of the key differences between manufacturing in Vietnam and China is the cost of shipping products to international markets, particularly in terms of sea freight. Vietnam’s smaller scale of export operations and relatively underdeveloped logistics infrastructure mean that sea freight from Vietnam can be more expensive than from China. According to industry estimates, shipping a 20-foot container from Vietnam to Europe or the USA can cost around 10% more than from China due to these logistical challenges.

Shipping costs breakdown:

| Route | Estimated Cost (20′ container) | Average Shipping Time |

|---|---|---|

| Vietnam to Europe | $2,500 – $3,000 | 35-45 days |

| China to Europe | $2,200 – $2,800 | 30-40 days |

| Vietnam to USA | $3,000 – $3,500 | 25-35 days |

| China to USA | $2,500 – $3,200 | 20-30 days |

In addition, while Vietnam is emerging as a popular manufacturing hub due to its low labor costs, its relatively smaller logistics network means that suppliers often face delays in finding the right partners for their shipments. Whether you’re managing FOB or CIF shipping terms, costs will naturally increase as you need to account for the longer lead times and the scarcity of reliable logistics partners in the region.

Is Vietnam more expensive than China?

When evaluating manufacturing costs, it’s essential to consider both direct production costs and logistics costs. So, is manufacturing in Vietnam really more expensive than in China?

While Vietnam offers lower labor costs, higher logistics costs, fewer service options, and longer transit times could offset those savings.

On the surface, manufacturing in Vietnam is often considered a cost-effective alternative to China due to lower wages and more competitive production rates. However, the logistics side of the equation is where differences become apparent. The scarcity of freight forwarders in Vietnam compared to China means that many businesses must spend more time sourcing and negotiating freight contracts. As a result, they might face delays and higher logistics expenses, making Vietnam seem less affordable in some cases.

For example, freight forwarding fees from Vietnam to ports like Haiphong or Ho Chi Minh City can be more costly than those from major Chinese ports like Shanghai or Shenzhen. On average, expect to pay approximately $600 for a 20-foot container’s freight forwarding from Vietnam to the nearest port, whereas in China, these services are often cheaper and more readily available.

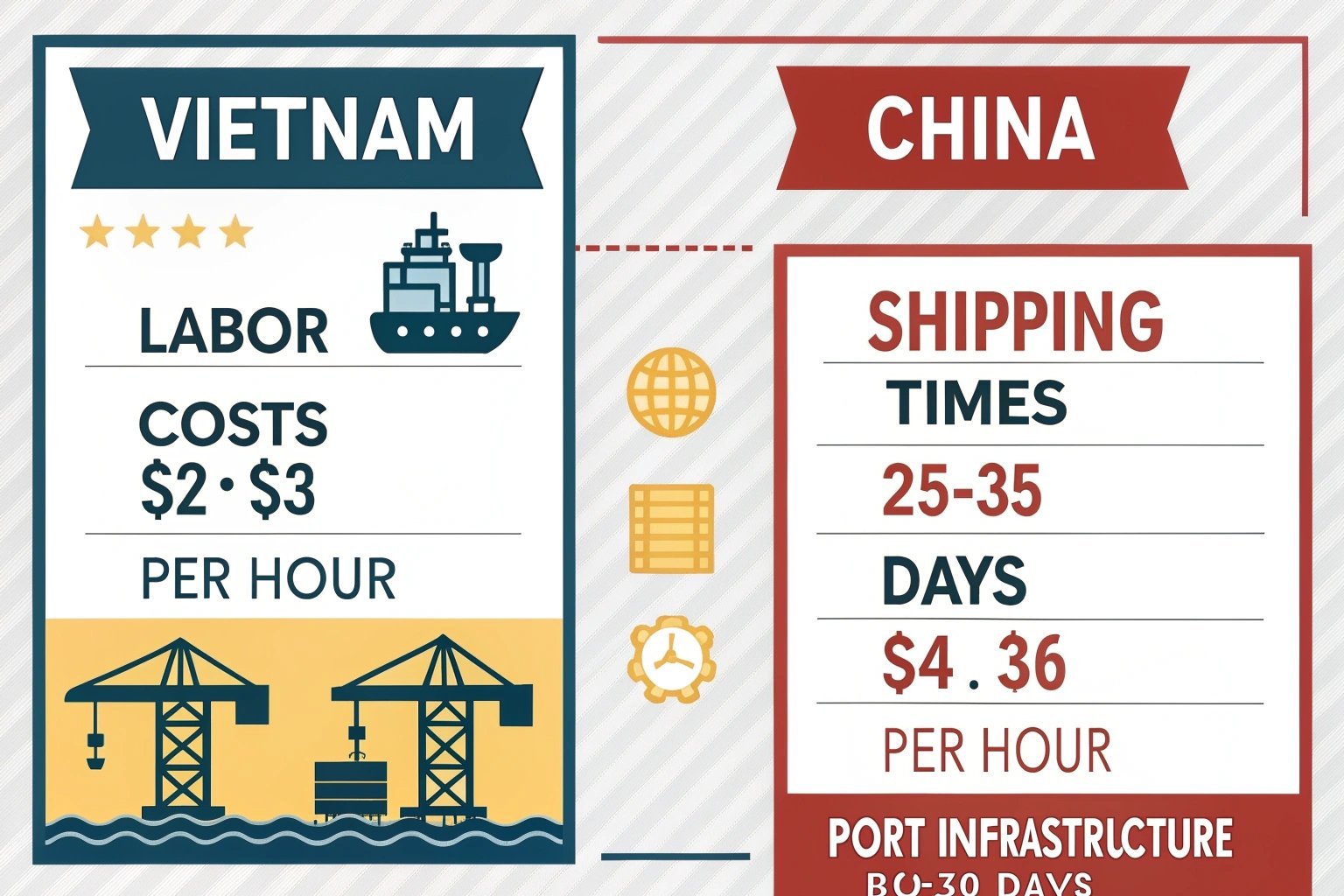

Here’s a simple comparison of labor and freight costs:

| Cost Element | Vietnam | China |

|---|---|---|

| Average Labor Cost per Hour | $2 – $3 | $4 – $6 |

| Freight Forwarding Fee (20′ container)1 | $600 | $450 |

| Port Infrastructure | Less developed | Well-developed |

| Shipping Time (Asia to US/Europe) | 25-35 days | 20-30 days |

While the labor costs in Vietnam may seem attractive, the higher logistics and transportation costs can add up quickly, making the overall cost difference less significant. If your primary concern is logistics and speed, China’s more developed infrastructure may still be the better choice despite the higher labor costs.

What are the pros and cons of manufacturing in Vietnam?

Manufacturing in Vietnam offers unique advantages and challenges. Let’s explore both.

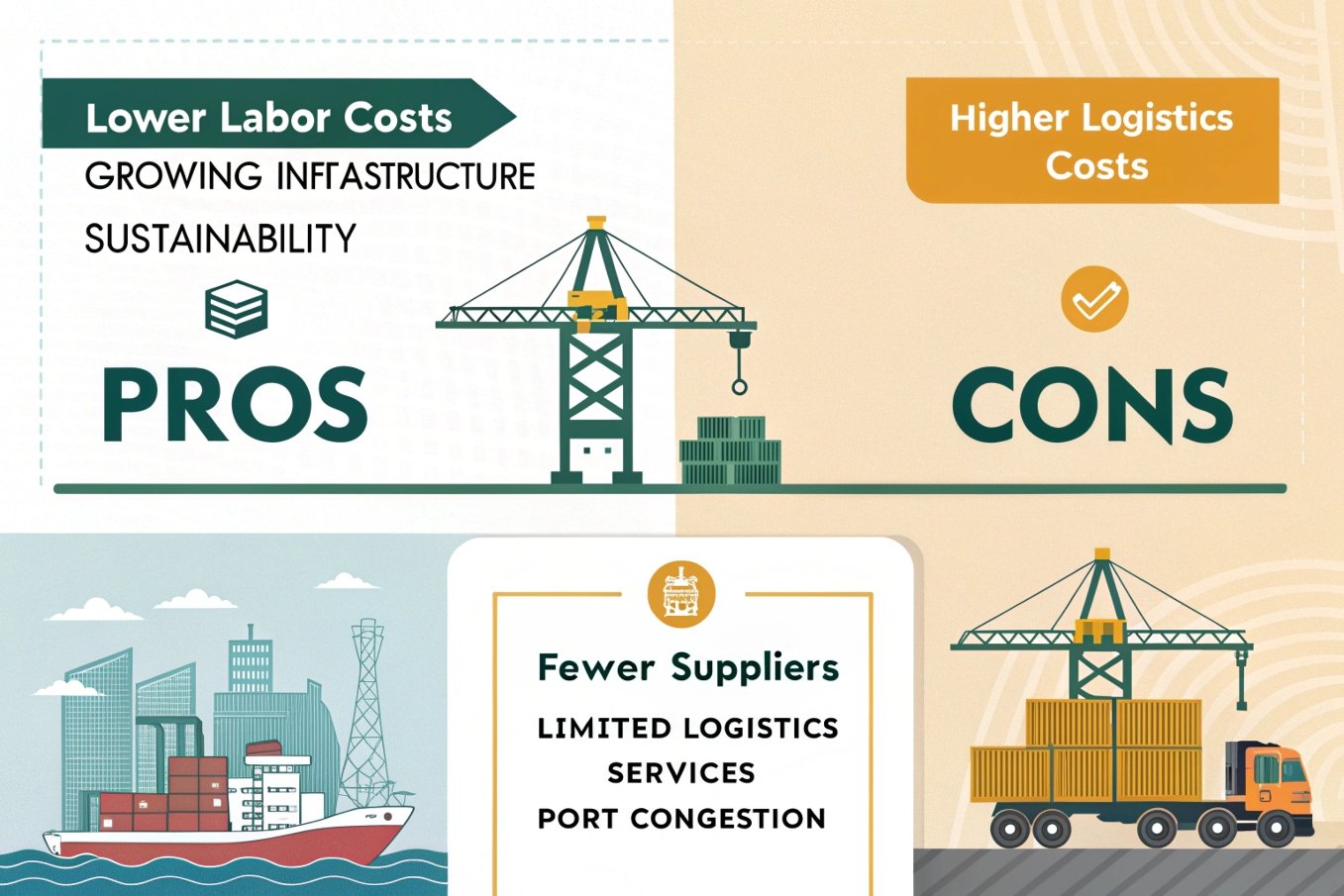

Pros of manufacturing in Vietnam:

- Lower Labor Costs2: Vietnam offers highly competitive labor costs, making it a great option for labor-intensive industries such as textiles, footwear, and electronics assembly.

- Trade Agreements: Vietnam is a member of several Free Trade Agreements (FTAs), such as the Comprehensive and Progressive Agreement for Trans-Pacific Partnership (CPTPP) and the EU-Vietnam Free Trade Agreement (EVFTA), which can help reduce tariffs for goods shipped to various markets.

- Growing Infrastructure: While not as advanced as China’s, Vietnam’s port infrastructure and logistics networks are rapidly improving, especially in Ho Chi Minh and Haiphong.

- Sustainability Focus: Vietnam is increasingly becoming a leader in eco-friendly manufacturing, with a growing number of companies focused on sustainable production methods.

Cons of manufacturing in Vietnam:

- Logistics Challenges3: As mentioned earlier, logistics costs are higher than in China, and there are fewer freight forwarding companies available. This can lead to delays and inefficiencies.

- Limited Availability of Suppliers: Unlike China, where manufacturers are abundant and can cater to nearly every industry, Vietnam has fewer suppliers in certain sectors, which can limit options for sourcing.

- Fewer Logistics Services: Vietnam’s freight forwarding industry doesn’t offer the same breadth of services as China, and the lack of LCL services means that manufacturers must often rely on FCL shipments, which could increase costs for smaller orders.

- Port Congestion: Vietnam’s ports, especially in Ho Chi Minh City, can experience congestion during peak shipping times, further contributing to delays and potential increased costs.

Here’s a quick look at the pros and cons:

| Pros | Cons |

|---|---|

| Lower labor costs | Higher logistics costs |

| Free trade agreements | Limited supplier base in some sectors |

| Improving infrastructure | Fewer freight forwarding options |

| Focus on sustainable production | Port congestion during peak seasons |

In conclusion, while Vietnam offers many advantages, such as competitive labor rates and access to free trade agreements, its logistics infrastructure is still catching up. These logistical hurdles could make Vietnam less attractive for businesses that require fast and efficient international shipping.

Conclusion

The choice between manufacturing in Vietnam or China comes down to balancing the costs of labor, logistics, and the specific needs of your business. Vietnam offers significant labor savings, but the added logistics challenges may offset these savings for some companies.

Understanding freight forwarding fees can help you make informed decisions about shipping costs and logistics. ↩

Exploring the benefits of lower labor costs can provide insights into cost-effective manufacturing strategies. ↩

Learning about logistics challenges can help businesses strategize and mitigate potential issues in their supply chain. ↩