The application of aluminum alloy casting in the automotive industry mainly lies in its lightweight, high strength, and excellent castability, which can reduce the total weight of automobiles, reduce fuel consumption, improve energy efficiency, and reduce exhaust emissions. Through processes such as high-pressure casting, aluminum alloy can be used to manufacture engine components, transmission casings, chassis components, body structural components, and wheel hubs.

Die casting, abbreviated as die casting, fills the mold cavity with molten metal under a certain pressure. The casting structure is dense, with high mechanical properties, precise dimensions, and small machining allowance. According to pressure, it can be roughly divided into low-pressure casting and high-pressure casting. In recent years, car manufacturers have faced pressure to improve fuel efficiency and reduce emissions. Aluminum castings have been widely used in the automotive industry due to their unique characteristics such as light weight, high strength, good thermal and electrical conductivity, good corrosion resistance, and good recyclability.

Lightweight

Due to the low density of aluminum alloy, its application in automobile manufacturing can significantly reduce the overall weight of vehicles, further improve fuel economy, and reduce carbon dioxide emissions. For example, for a car weighing 1300 kilograms, reducing weight by 10% can reduce fuel consumption by about 8%, which means saving about 0.7 kilograms of fuel every 100 kilometers traveled. By replacing traditional heavy steel components with lightweight aluminum alloy castings, components such as the engine hood and doors can reduce weight by 40% to 50%, effectively reducing vehicle burden and improving overall performance.

Corrosion resistance and durability

Aluminum alloy has excellent performance in resisting environmental corrosion, which means that the application of aluminum alloy castings in automobiles can help extend the service life of vehicles and reduce maintenance costs. In addition, the heat resistance and strength of aluminum alloys are also suitable for high temperature environment components such as engines and transmissions.

Sustainable and recyclable

Aluminum is one of the most abundant metals on Earth and can be almost infinitely recycled without losing its essential properties. The automotive industry chooses to use aluminum alloy casting components, which not only reduces the impact on the environment but also enhances the lifecycle value of materials. Recycling and reusing aluminum alloys has become an important aspect of promoting sustainable development in the automotive industry.

Cost savings

Although the initial cost of aluminum alloy may be higher than other materials, its cost-effectiveness throughout its lifecycle is significant. In the long run, the application of aluminum alloy casting in the automotive industry can help reduce fuel and maintenance costs, saving money for manufacturers and consumers.

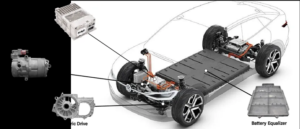

Application examples

Engine components: piston, cylinder block, cylinder head, crankshaft, etc.

Transmission housing: an aluminum alloy casting used to surround and protect the transmission.

Body structural components: including frame, door, cover plate, and roof, etc.

Suspension system components, such as suspension brackets and wheel hubs.

Due to its excellent performance, aluminum castings play a crucial role in modern automotive design and manufacturing, helping to improve fuel efficiency, reduce emissions, and enhance performance. With the continuous development and innovation of aluminum alloy casting technology, the application of aluminum alloys in the future automotive industry will further expand, thereby promoting more efficient, environmentally friendly, and sustainable automotive design and manufacturing.

Thank you for reading our article. If you need related products or have any questions or suggestions about our products, please don’t hesitate to contact us by sending an email, and we will reply to your email as soon as possible.