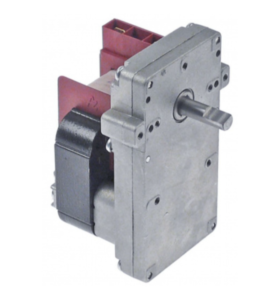

We recently helped an Italian trader to solve a technical problem with his product.

When the client came to us he told us he had an old supplier, but his old supplier could not solve the problem of broken teeth. Therefore he wants to seek our help and ask us if we have a good solution.

Material Testing

The client sent us the previous samples, and we performed component analysis and performance tests on these samples. The test found that because the density of sintered iron parts is lower than that of solid steel, it cannot meet the client’s requirement for tooth torque 13N.

Therefore, our engineers matched three different material formulations based on their experience and finally selected the material that can meet the performance requirements of the client after testing.

Spot Inspection

Because the problem of broken teeth cannot be eliminated 100%, the last solution we provide to the client is to increase the proportion of spot inspections of each batch of products. At the same time, to avoid the loss of product recall caused by the recurrence of broken teeth, once any unqualified products are found, we will conduct a full inspection of the entire batch of gears.

Because the problem of broken teeth cannot be eliminated 100%, the last solution we provide to the client is to increase the proportion of spot inspections of each batch of products. At the same time, to avoid the loss of product recall caused by the recurrence of broken teeth, once any unqualified products are found, we will conduct a full inspection of the entire batch of gears.

Now we have been supplying to this client for two years and have not received any feedback on defective products during this period.